1. Introduction: The Foundation of Replication

From duplicating a sculptor's masterpiece to producing batches of unique resin jewelry, the ability to perfectly replicate an object is invaluable. Liquid Silicone Rubber (LSR) for mold making is the cornerstone of this process. It is a versatile, high-performance material that bridges the gap between a creative idea and a tangible, reproducible product.

This guide will introduce you to the world of liquid silicone, with a special focus on our core product lines: Platinum-Cure, High transparency, and Tin-Cure Silicones, empowering you to select the perfect material for your replication needs.

2. What Is Liquid Silicone Rubber?

At its core, Liquid Silicone Rubber(LSR) for mold making is a synthetic polymer primarily composed of silicone—a material derived from silicon, an element found in sand. Its liquid state before curing allows it to capture surface details at a microscopic level, while its cured state provides the flexibility and strength necessary for repeated demolding.

The Two-Part System (A&B Components)

Unlike many other rubbers, Liquid Silicone Rubber(LSR) comes in two parts: Base (Part A) and Curing Agent (Part B). The curing process, known as addition curing, is triggered when these two parts are mixed in a precise 1:1 ratio by weight or volume. This reaction, facilitated by a platinum catalyst, creates cross-links between polymer chains without producing any by-products, resulting in a stable, non-shrinking, and low-odor material.

3.Platinum-Cure vs. Tin Cure Silicone: Professional Selection Guide

Platinum vs. Tin Cure: Choosing the Right Catalyst for Your Mold.

The most critical distinction in liquid silicone rubber is the curing system: Platinum-Cure or Tin-Cure (Condensation-Cure). Your choice profoundly impacts mold quality, performance, and application suitability.

Comparison Table: Platinum-Cure vs. Tin-Cure Silicone

| Feature | Platinum-Cure Silicone | Tin-Cure Silicone |

| Curing Mechanism | Addition reaction, no by-products | Condensation reaction, releases alcohol |

| Shrinkage | Exceptionally Low (< 0.1%), with exceptional dimensional accuracy | Noticeable (0.3% - 0.8%), affecting precision |

| Tear Strength & Durability | Very High, long mold life (100+ casts) | Moderate, can become brittle, shorter lifespan |

| Heat Resistance | Better, typically 250°C | General, typically <160°C |

| Inhibition Issues | Sensitive to sulfur, tin, and other inhibitors | Highly resistant to inhibition |

| Food Safety & Certifications | Easily certified FDA, LFGB compliant | Difficult to certify; not suitable for direct food contact. |

| Odor | Virtually odorless | Noticeable vinegar or alcohol smell |

| Cost | Higher | More Economical |

| Best For | High-detail molds, production runs, food-safe applications, maximum dimensional accuracy | One-off crafts, low-cost prototypes, use with inhibitor-prone materials (e.g., certain clays, woods) |

4. Why Choose Our Liquid Silicone for Your Mold Making?

Our LSR is engineered to provide a perfect balance of properties essential for creating high-quality, long-lasting molds.

5. Key Technical Parameters Decoded

Understanding these specifications will help you select the perfect LSR for your project.

| Parameter | Description | Importance for Mold Making |

| Viscosity | The fluidity of the mixed liquid. | Low viscosity (e.g., 3,000 - 10,000 mPa·s) is key for capturing fine details and avoiding air bubbles. |

| Pot Life | Time available to work with the mixed silicone before it becomes too thick to pour. | A longer pot life (e.g., 30-60 minutes) is beneficial for large or complex molds. |

| Cure Time | Time required for the silicone to fully solidify at room temperature. | A balance is needed between a workable pot life and a reasonable demolding time (e.g., 4-8 hours). |

| Shore Hardness | Measures the flexibility of the cured rubber (e.g., Shore A 20 is very soft, Shore A 40 is firm). | Softer (Shore A 10-20) for complex undercuts. Firmer (Shore A 25-40) for flat surfaces and durability. |

| Tear Strength | Resistance to tearing once a cut is initiated. | High tear strength is critical for mold longevity, especially with delicate master models. |

6. How to Choose the Right Silicone for Your Process?

Choose Platinum Silicone. Its low shrinkage and durability are unmatched.

Choose our High Transparency Platinum Silicone. It offers all the benefits of platinum cure with optical clarity.

Choose Tin-Cure Silicone. It provides a reliable, cost-effective solution.

7. Types of Liquid Silicone for Mold Making

Platinum-Cure Silicone: The premium choice for professionals. Suitable for casting molds for metal crafts, alloy automotive parts, epoxy resin, polyester resin, polystyrene, vinyl plastics, paraffin wax, large cement components, cultured stone, concrete, high-precision prototype models, as well as food applications and the production of long-lasting production molds.

High Transparency Platinum Silicone: A subtype of platinum silicone with exceptional optical transparency. Perfect for creating "invisible" molds for embedded objects or when you need to see the casting material perfectly.

Tin-Cure Silicone: The economical and versatile workhorse. Suitable for mold making of plaster, GRC, cement, resin, artificial stone, candles, statues, Buddha statues, Christmas decorations, figures, railings, ceilings, bases, fountains, handmade soaps, etc., and when working with materials that may inhibit platinum cure.

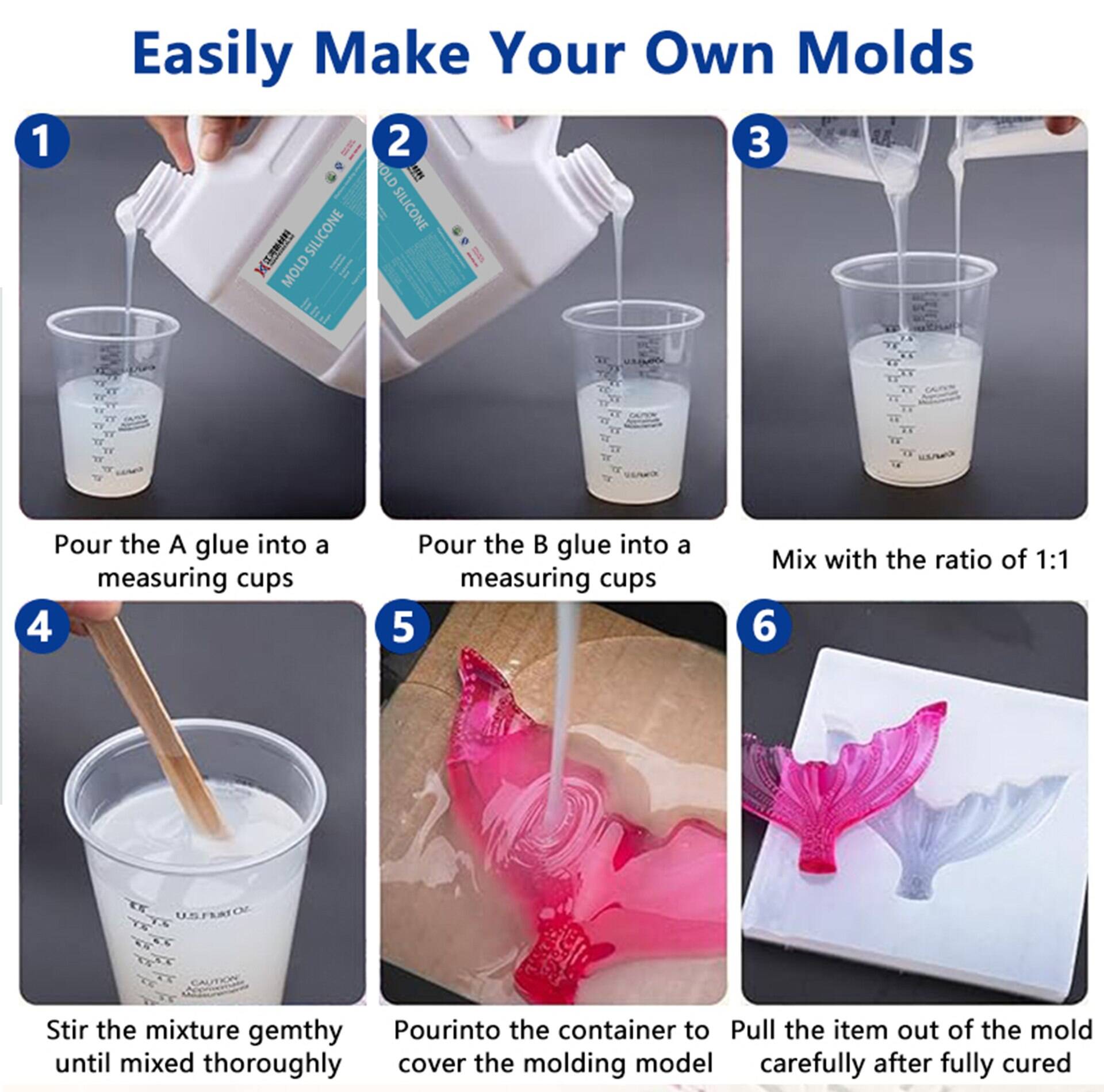

8. Step-by-Step Mold Making

9. Troubleshooting Common Issues

(1)Incorrect Mixing Ratio

Cause: Failure to strictly follow the weight or volume ratio of Part A to Part B. Even a slight deviation can prevent full curing.

Fix: Always use a digital scale for precise weighing by weight. Do not "eyeball" volumes with cups. Double-check the mix ratio on the product TDS.

(2)Inadequate or Uneven Mixing

Cause: Parts A and B are not mixed thoroughly and evenly, preventing the catalyst from triggering the reaction throughout the system.

Fix: Scrape the sides and bottom of the mixing cup and mix for a full 3-5 minutes until the color and consistency are perfectly uniform with no streaks.

(3)Catalyst Poisoning (Inhibition)

This is the most common cause of cure failure for Platinum Silicone.

Cause: The platinum catalyst is "poisoned" and deactivated by contact with certain substances, e.g., sulfur, tin, amines. Common sources: certain modeling clays, latex gloves, tin-cure silicones, some woods, paints/sealants.

Fix:

(4)Temperature Too Low

Cause: Chemical reaction rates slow down significantly with lower temperatures. Cold environments can virtually halt the curing process.

Fix: Ensure the working and curing environment is at 20°C - 25°C (68°F - 77°F). In cold weather, pre-warm the silicone components (in sealed containers) or use a warming cabinet.

(5)Old or Expired Material

Cause: Silicone (especially the Part B curing agent) has a shelf life. Products that are expired or exposed to extreme temperatures/humidity can degrade.

Fix: Check the manufacture date and shelf life on the packaging. Store silicone in a cool, dry, and dark place. Practice first-in-first-out (FIFO) inventory management.

(6)Using the Wrong Curing Agent

Cause: Using a Part B from a different brand or type, or mismatching A and B components.

Fix: Never mix Part A and Part B from different brands or batches. Even within the same brand, ensure you are using the originally paired curing agent.

(7)Moisture Contamination

Cause: Condensation-cure (Tin) silicones are moisture-sensitive. Water in mixing containers or on tools, or high ambient humidity, can interfere with curing.

Fix: Ensure all tools and containers are completely dry. Be extra cautious in high-humidity environments.

(8)Inadequate Pot Life Management

Cause: Pouring after the silicone has already begun to thicken and approach its gel state, preventing it from leveling and potentially causing incomplete curing.

Fix: Know the pot life of your product. Prepare everything in advance to ensure mixing and pouring are completed within this time.

(9)Bulk Effect (Exotherm Management)

Cause: When mixing a very large volume at once, the heat generated by the curing reaction cannot dissipate quickly enough, causing a rapid internal temperature spike. This can lead to scorching, cracking, bubbles, and curing issues.

Fix: For large volume molds, recommend casting in layers. Do not pour each layer too thick; allow the previous layer to complete its exotherm before pouring the next.

(10)Poor Quality or Counterfeit Products

Cause: Using silicone from unverified sources, with unstable composition or counterfeit products.

Fix: Source your materials from a reputable, professional manufacturer (like us). Consistent quality is the foundation of success.

10. Applications

Resin Casting & Art: Creating custom jewelry, figurines, and decorative objects.

Prototyping & Model Making: Producing small batches of functional parts for testing and presentation.

Culinary Arts: Crafting custom chocolate, candy, and ice cube molds.

Cosmetics & Soap Making: Forming unique shapes for soaps, candles, and bath bombs.

11. Conclusion: Your Partner in Creation

Liquid Silicone Rubber is the unsung hero behind countless creations. Its ability to perfectly capture detail and withstand repeated use makes it an indispensable tool for anyone serious about replication and manufacturing.

Partner with us for:

Consistently high-quality LSR with verified technical specifications.

Expert technical support for your specific mold making challenges.

Custom formulation capabilities for unique application requirements (OEM/ODM).

Start Your Mold Making Journey Today!

Shop Our Liquid Silicone Rubber for Molds

Download Our Comprehensive Mold Making Guide (PDF)

Get a Custom OEM Formulation Quote

Hot News

Hot News2026-01-14

2026-01-06

2025-12-27

2025-12-26

2025-12-26

2025-12-25