2:1 Ratio Crystal Clear Epoxy Resin And Hardener for Crafts

Model: 2120A-C+2120B-M3-2 Mix Ratio: 2:1

Key Features:

- Rapid Surface Cure - Surface dry in 8-12 hrs, full cure in 24-36 hrs.

- Excellent Self-Debubbling - High clarity without surface ripples.

- Crystal Clear Finish – Delivers high transparency for flawless, glass-like results.

- Optimal Viscosity – Low viscosity formula ensures excellent flowability and easy application.

Technical Specifications:

| ☆ Color: Light Blue Transparent | ☆ Mixed Viscosity: 500±200 mPa·s |

| ☆ Pot Life: 30-40 min | ☆ Hardness: Shore D 82±2 |

Perfect For:

| ☆ Artistic Creations | ☆ Energy Module Potting |

| ☆ Electronic Module Sealing | ☆ Confidential Masking |

| ☆ Mold Casting | ☆ Harsh Environment |

- Overview

- Recommended Products

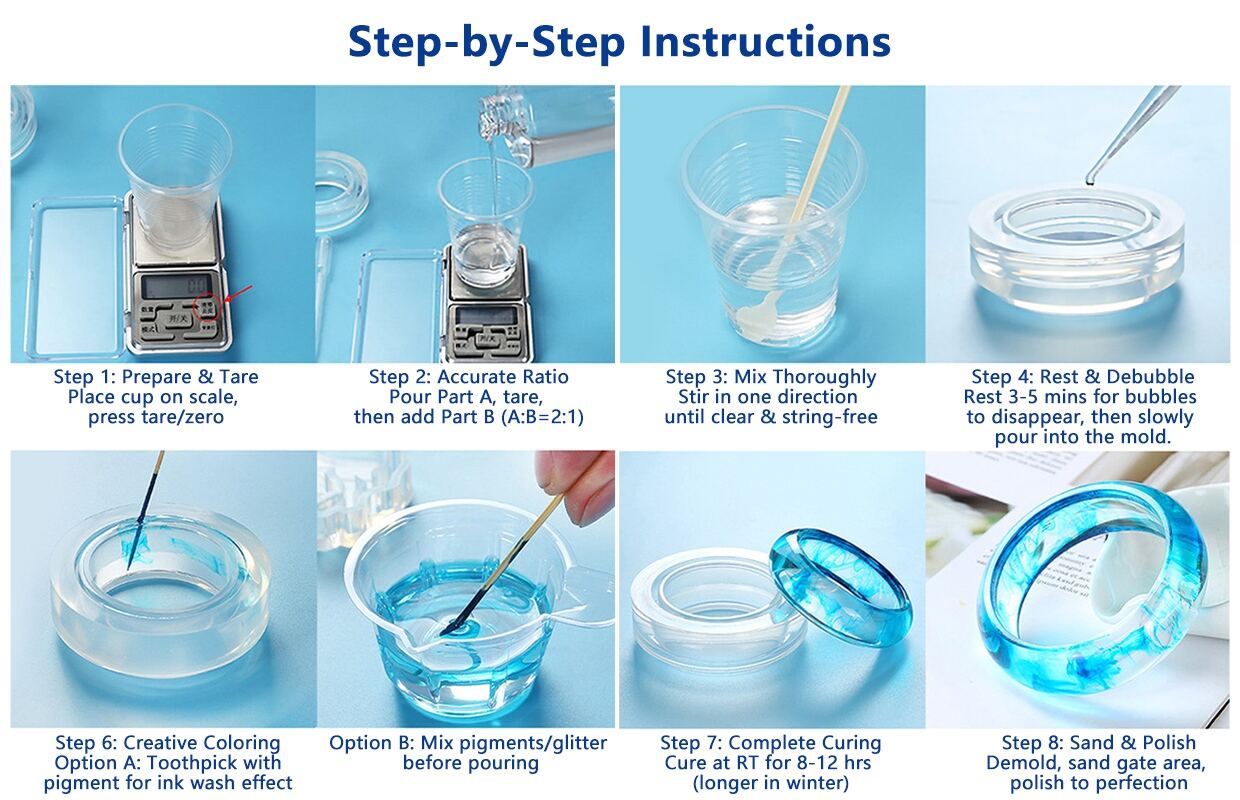

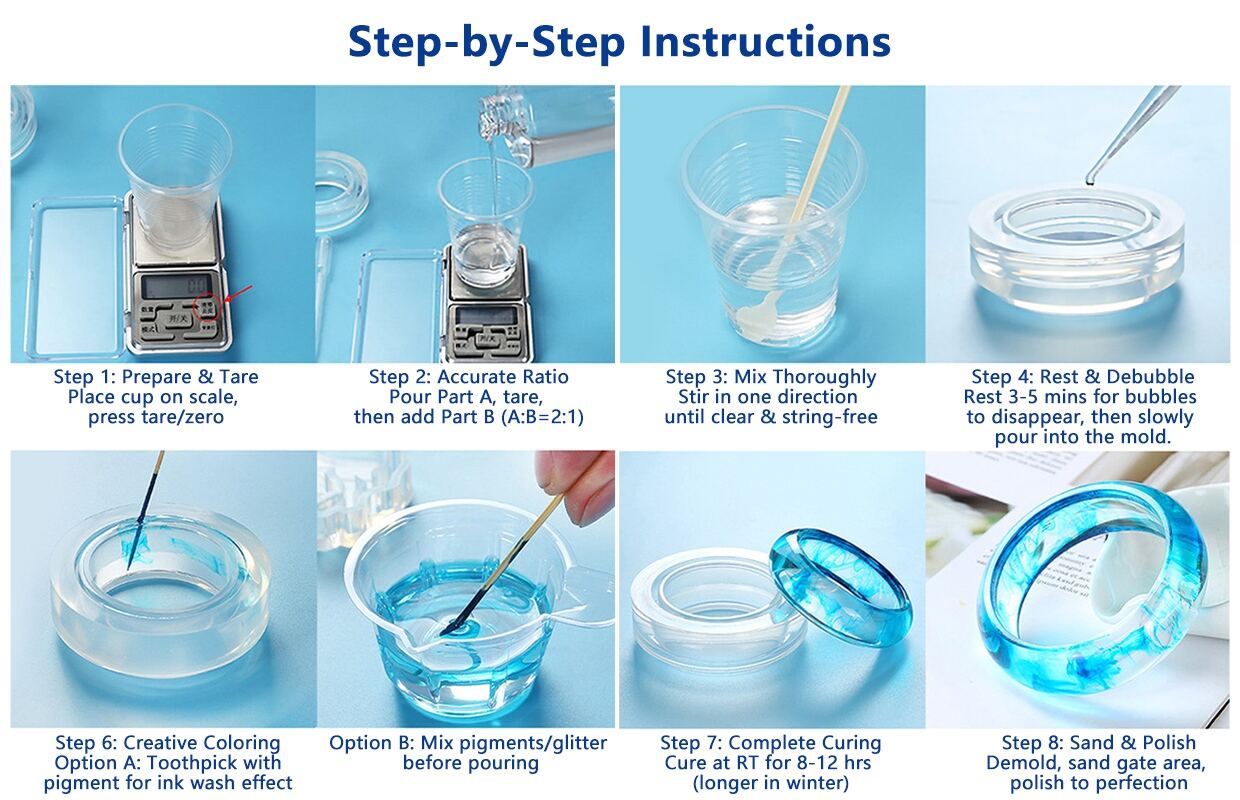

- Place a clean mixing cup on the digital scale and press the "Tare/Zero" button.

- Pour Part A into the cup until reaching the target weight (e.g., 20g).

-

Press "Tare" to zero the scale, then pour Part B to the corresponding weight (e.g., 10g).

-

Using a stirring stick, stir at a constant speed in one direction gently.

-

Continue stirring for 2-3 minutes until the mixture becomes uniformly transparent and string-free.

-

Let the mixed resin rest for 3-5 minutes to allow bubbles to rise and burst naturally.

-

Observe the resin surface and proceed only after most bubbles have disappeared.

-

Gently pour the de-bubbled resin into the mold.

-

Dip a toothpick into a tiny amount of pigment and lightly touch the resin surface.

- Allow the pigment to diffuse naturally, creating unique ink wash patterns.

-

Add pigments, glitters, or other decorations to the de-bubbled resin.

-

Stir gently for 30-60 seconds until evenly distributed.

- Pour the mixture slowly into the mold, gently tapping to remove remaining bubbles.

-

After 8 hours, test edges with the back of a clean finger.

-

Surface should feel dry and non-tacky, no fingerprint residue with light pressure.

-

Mild handling or surface cleaning is acceptable at this stage.

-

After 24 hours, conduct a comprehensive hardness test.

-

Light nail scratch should leave no marks or dents.

- Product is ready for normal use, processing, or polishing.

-

Safety First: Operate in a well-ventilated area, away from ignition sources. Avoid skin and eye contact.

-

Mix as Needed: Estimate quantity based on the 40-minute pot life to avoid waste.

-

Adapt to Conditions: Preheat Component A if temperature <15°C; use heat-assisted curing if humidity >85% to prevent surface whitening.

- Safe Keeping: Keep out of reach of children.

-

Storage Conditions: Store in a cool, dry place below 25°C (77°F). Keep away from direct sunlight, heat sources, and humid environments.

- Packaging & Stability: The product has a shelf life of 6 months from the date of manufacture when stored unopened in its original container under recommended conditions. Once opened, reseal tightly and use as soon as possible. Do not leave exposed to air for extended periods.

Professional Epoxy Resin Manufacturing Experts

Shenzhen Jianghe New Materials Technology Co., Ltd. is a leading developer and manufacturer of high-performance polymer materials, including epoxy resin, PU resin, UV resin, and liquid silicone rubber. As an integrated source factory combining R&D, production, and sales, we operate a 20,000㎡ modern production base in Dongguan, certified with ISO9001 and other international standards. Supported by advanced equipment, a dedicated R&D team, and a strict QC system, we deliver over 25,000 tons of stable, high-quality, and cost-effective products annually to clients in over 100 countries. We specialize in customized formulations and OEM/ODM services, empowering industries from crafts and furniture to electronics and composites with reliable material solutions.

Key Advantages & Features

01: Distinctive Visual Identity

Innovative light blue transparent appearance provides not only aesthetics but also a unique visual identifier for your products. In potting/encapsulation applications, the light blue color aids quick identification and differentiation between batches or models.

02: Efficient Curing Performance

Optimized formulation achieves surface dry in 8-12 hrs and full cure in 24-36 hrs, significantly shortening production cycles. Maintains high hardness (Shore D 82) and excellent heat resistance (HDT 60°C).

03: Excellent Processing Properties

Moderate mixed viscosity (500±200 mPa·s) with excellent self-debubbling and leveling ensures bubble-free filling of complex molds and mirror-smooth surface finish.

Detailed Technical Specifications

| Property | Part A | Part B |

| Color | Light blue, transparent | Light blue, transparent |

| Density (g/cm³) | 1.07±0.05 | 0.95±0.03 |

| Viscosity (mPa·s) | 2000±500 | 100±50 |

| Mix Ratio (By Weight) | A : B=2:1 (weight ratio) | |

| Pot Life (100g, 25°C) | 30-40 min | |

| Viscosity After Mixing | 500±200mPa.S | |

| Surface Dry | 8-12 hours | |

| Full Cure | 24-36 hours | |

| Hardness (Shore D) | 82±2 | |

| Water Absorption (%) | <0.1 | |

| Shelf Life | 6 months | 6 months |

| Storage Temperature | 15°C to 25°C | |

Usage Guide & Steps

Step 1: Precise Measurement

➤ Key Tip: Always maintain the A:B = 2:1 weight ratio.

Step 2: Thorough Mixing

➤ Key Tip: Scrape the cup walls and bottom during stirring to ensure no unmixed areas.

Step 3: Resting & De-bubbling

Step 4: Creative Crafting

Option A: In-mold Coloring (Ink Wash Effect)

Option B: Pre-mix Coloring

Step 5: Curing & Quality Verification

Room Temperature Curing Guide (15-25°C)

Phase 1: Surface Dry Check (8-12 hours)

Phase 2: Full Cure Completion (24-36 hours)

Safety, Handling & Storage Guidelines

1. For Safe Operation & Mixing

2.Storage And Shelf Life

Applications & Project Gallery

1. Artistic Creation Applications

Epoxy Resin for Artistic Creations - High transparency self-debubbling solution for drip art, resin jewelry, and decorative molds. Perfect for DIY enthusiasts and art studios creating fluid paintings, handmade jewelry, and decorative castings, ensuring mirror-smooth surfaces and lasting clarity.

2. Energy Module Potting Solutions

Epoxy Potting Compound for Energy Inverters - Specifically designed for PV inverters, energy storage battery packs, and EV power modules. Offers excellent electrical insulation, high temperature resistance (HDT 60°C), and moisture protection, ensuring long-term stability of energy equipment in harsh environments.

3. Electronic Module Sealing Protection

PCB Moisture-proof Sealing Epoxy - Ideal for waterproof and moisture-proof encapsulation of sensors, controllers, and communication modules. Light blue transparent appearance facilitates quality inspection, while low viscosity (500±200mPa·s) ensures complete filling of complex structures, providing reliable moisture barrier for precision electronic components.

4. Military Confidential Masking Applications

Military-grade Epoxy for Confidential Shielding - Provides secure physical shielding for military chips, confidential circuits, and sensitive electronic components. Through opaque or specific color encapsulation, prevents reverse engineering and visual inspection while maintaining excellent mechanical protection and environmental resistance.

5. Industrial Mold Casting Applications

Industrial Mold Transparent Casting Epoxy - Suitable for high-quality casting of composite samples, transparent parts, and display molds. Excellent leveling and self-debubbling properties ensure mold replication accuracy, with light blue color facilitating demolding observation, offering professional solutions for industrial prototyping.

6. Harsh Environment Protection Solutions

Outdoor/Underwater Equipment Protection Epoxy - Specifically designed for enhanced protection of outdoor monitoring equipment, underwater sensors, and marine engineering devices. Features ultra-low water absorption (<0.1%), weather resistance, and chemical stability, providing long-term protection for equipment exposed to moisture, salt spray, UV, and other harsh conditions.

OEM Customization Service

1. Customized formulation: Viscosity, flowability, curing time, hardness, transparency, color, and various functional additives (anti-yellowing, UV resistance, flexibility enhancement, flame retardancy, etc.) can be adjusted according to needs to meet different industry application scenarios.

2. Packaging Customization: Multiple packaging sizes are available to suit your production scale, including 1kg, 5kg, 20kg, 25kg, and 200kg drums. All packaging follows international shipping standards to ensure safety and durability.

3. Private Label: Supports brand customization, including bottle label design, outer packaging printing, and logo labeling, helping brand owners and wholesalers quickly build their own brands and enter the market.

4. Supplies and Kits: Pre-mixed kits (such as resin + resin pigment + mold + tools, etc.) are provided according to your end product.

5. Color matching and functional additives: Color matching services are supported, and special effects such as metallic, transparent, and pearlescent colors can be added, as well as various functional additives such as UV stabilizers, defoamers, scratch and abrasion resistant agents, and flame retardants.

6. Sample support: We support sample orders for performance testing before mass production. This ensures compatibility with your process, equipment, and application requirements.

7.Technical consultation and process guidance: Engineers provide one-on-one technical guidance on construction suggestions, curing conditions, mixing ratios, application processes, etc., to help you solve practical problems.

Why Choose Our Customization Services?

1. Fast Response — Initial Technical Proposal Within 72 Hours

Once we receive your requirements, our engineering team will provide an initial formulation direction or technical recommendation within 72 hours. This significantly shortens your R&D cycle and speeds up time-to-market.

2. Cost Advantage — 15–30% Lower Than Trading Companies

As a factory with no middlemen, we offer highly competitive OEM pricing while maintaining strict quality standards. Ideal for distributors, factories, and brand owners seeking stable and scalable supply.

3. Confidentiality Guaranteed — 100% NDA Support, Formulations Never Disclosed

Every custom project can be secured with an NDA. We protect your formulations, data, and intellectual property with strict confidentiality standards and never share them with third parties.

4. End-to-End Control: One-Stop Service from Raw Materials to Delivery

Full in-house control over formulation, production, filling, private labeling, packaging, and logistics ensures consistent quality and stable supply.

5. 17+ Years of Material Manufacturing Expertise

With deep expertise in epoxy resin, PU resin, UV resin, liquid silicone rubber, and gypsum powder, we understand the performance needs of various industries including electronics, crafts, automotive, LED, molds, and flooring.

6.Technical Core: In-House R&D Center and Engineering Team

Experienced application engineers provide one-on-one support in formulation tuning, process optimization, and troubleshooting to ensure optimal performance.

7. Stable Quality — ISO9001 Certified Production

We follow strict quality control standards under ISO9001:2015. Every batch is traceable, stable, and tested to meet your specifications.

8. Fast Sampling & Flexible MOQ

We support rapid sample production and low-MOQ orders, reducing risks for new product launches, distributors, and factory procurement.

9. Brand Empowerment: Complete Private Label and Packaging Customization

Full white-label services including label design, multi-size packaging, and brand logo printing to help you build a professional brand image with ease.

10.Global Delivery: Scalable Production and International Logistics Network

Own large-scale production facilities paired with a mature global logistics network ensure stable output and on-time delivery worldwide.

If You Need Customized Packaging Or Other Specifications, Please Contact Us.

FAQ:

1.Q: Does light blue affect light transmittance?

A: No. Our light blue is a very pale tint with minimal impact on light transmittance while providing good visual identification.

2.Q: How to accurately measure the 2:1 ratio?

A: We recommend using a digital scale for precise weighing by weight. For small batches, graduated dual-component mixing cups can be used.

3.Q: Can other colors be formulated?

A: Yes. We offer color customization service and can formulate specific colors per your requirements.

4.Q: How to use below 15°C?

A: We recommend pre-heating Part A to 30°C to improve flow, or consider using heat-assisted curing for acceleration.