Low Odor Anti Yellowing Fast Curing UV Resin for Resin Crafts

Model: 1121-27N3

Key Features:

- Superior Anti-Yellowing – Stays crystal clear, resists yellowing long-term.

- Quick Set & Hard Cure – Fast surface dry, hardens fully after cooling.

- Low Odor, User-Friendly – Minimal smell during use, odorless when cured.

- Strong Universal Adhesion – Bonds to glass, crystal, metal & more.

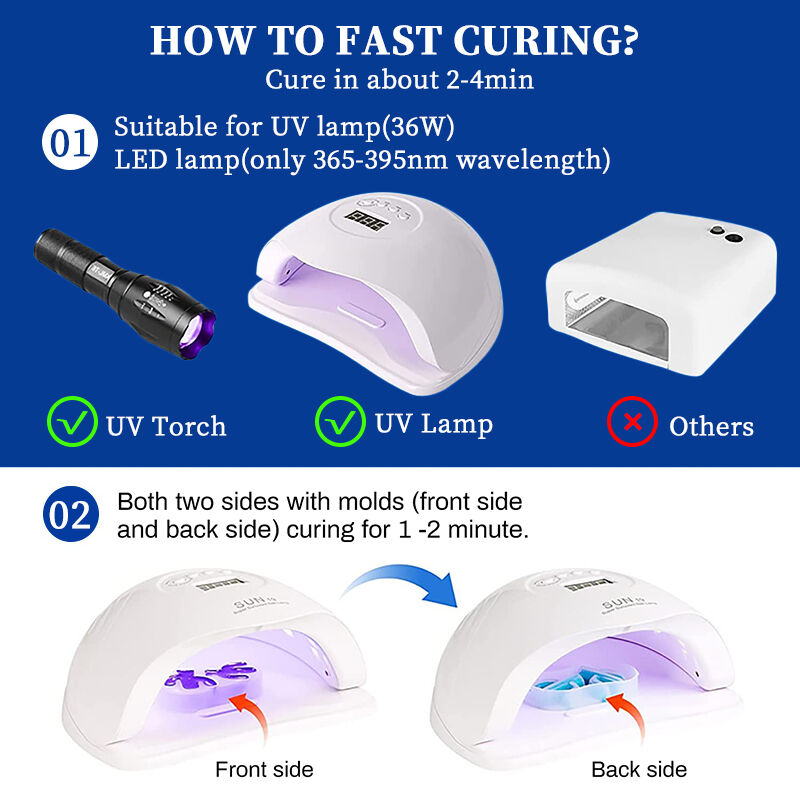

- Flexible UV Curing – Compatible with 6W to 72W lamps for adjustable speed.

Technical Specifications:

| ☆ Curing Method: Ultraviolet | ☆ Ultra-Clear UV Resin |

| ☆ Hardness: Shore D 85 | ☆ Viscosity: 1900 ± 300 |

Perfect For:

| ☆ Handmade DIY | ☆ Jewelry Making |

| ☆ Craft Art | ☆ Electronics Encapsulation |

| ☆ Surface Coating | ☆ Dried Flower Preservation |

- Overview

- Recommended Products

-

Avoid direct sunlight during operation to prevent premature curing

-

For thick molds, use a side-lighting UV lamp for even curing

- Clean tools promptly after use to prevent resin residue

-

The operating environment should be ventilated and should be kept away from fire. Closely sealed after use.

-

Avoid eye contact, in case of contact, wash with plenty of water and get medical attention immediately.

-

If contact skin, wrap it with a clean cloth or paper, and wash it with water and soap.

-

Keep away from children.

- Please take a trial before application to avoid usage mistakes.

-

Store at the temperature of 25°C or cool and dry place. Avoid sunlight, high temperatures, or a high-humidity environment.

- Use up as soon as possible when opened. It is strictly forbidden to be exposed to the air for a long time after it is opened to avoid affecting the quality of the products. The shelf life is 12 months at a room temperature of 25°C.

-

Crystal Trophy & Souvenir Encapsulation: Bonds crystal trophy components and encapsulates internal memorabilia (e.g., photos, badges) with nearly invisible seams, presenting an integrated, crystal-like finish.

-

Glass Art Ornament Creation: Used by artists to bond colored glass pieces for mosaics or 3D sculptures. The resin's high clarity and strength ensure structural integrity and visual transparency.

- Luxury Display Stand Bonding: Provides strong, aesthetically seamless bonding for custom acrylic or glass display stands for jewelry, watches, and luxury goods.

-

Dried/Preserved Flower Encapsulation Art: Encapsulates dried flowers, leaves, and moss into pendants, earrings, display trays, or paperweights. Its superior anti-yellowing property preserves floral colors for years, capturing a sense of "frozen time."

-

Insect/Mineral Specimen Making: Encapsulates specimens like butterflies, beetles, colored minerals, or shells for educational tools or artistic decorations. High clarity perfectly showcases specimen details.

- Creative Resin Art & Ocean-Themed Works: Creates dimensional resin paintings, ocean jars, or galaxy bowls using pigments, glitters, and models. The medium viscosity aids in shape-building without excessive flow.

- Modern Protective Coating for Cloisonné: A thin layer of resin is poured over finished cloisonné pieces, forming a smooth, mirror-like protective coat. This not only safeguards the fragile enamel and metal wires but also enhances the artwork's dimensionality and luster, making traditional crafts suitable for daily wear or display.

- Reinforcement for Heat-Shrink Film Encapsulation: Provides a secondary, waterproof, and scratch-resistant clear coating for important documents, ID cards, or souvenirs cards already encapsulated with heat-shrink film, widely used in schools and enterprises.

-

Personalized Glass Furniture Embellishment: Injects resin between glass tabletop layers to encapsulate photos, dried flowers, or gold foil, creating unique furniture pieces.

-

Transparent Magnet & Fridge Magnet Creation: Seals patterns inside resin with a magnet attached to the back, making highly transparent personalized fridge magnets or message board stickers.

- Creative Lighting & Shadow Décor: Casts resin around LED strips or specific molds to create artistic lampshades, night lights, or decorative panels with unique textures and light transmission.

-

Gundam/Figurine Scene Base Encapsulation: Creates transparent bases containing miniature landscapes (e.g., grass, water, fire effects) for models, "freezing" the scene in time.

-

Architectural & Diorama Model Protection: Applies a clear protective coating to fragile paper, wooden architectural models, or terrain dioramas, enhancing durability without obscuring details.

- Electronic Creative Project Encapsulation: Encapsulates and protects artistic installations or educational models containing LED lights or simple circuits, providing insulation and aesthetic appeal.

Professional UV Resin Manufacturing Experts

Shenzhen Jianghe New Materials Technology Co., Ltd. is a leading developer and manufacturer of high-performance polymer materials, including epoxy resin, PU resin, UV resin, and liquid silicone rubber. As an integrated source factory combining R&D, production, and sales, we operate a 20,000㎡ modern production base in Dongguan, certified with ISO9001 and other international standards. Supported by advanced equipment, a dedicated R&D team, and a strict QC system, we deliver over 25,000 tons of stable, high-quality, and cost-effective products annually to clients in over 100 countries. We specialize in customized formulations and OEM/ODM services, empowering industries from crafts and furniture to electronics and composites with reliable material solutions.

Key Advantages & Features

1.Long-Lasting Clarity with Leading Anti-Yellowing

Incorporates specialized UV absorbers and stabilizers to significantly delay photo-aging. Maintains initial clarity without yellowing or hazing, even under prolonged display window or sunlight exposure.

2. Fast Surface Dry & Instant Hardness on Cooling for Enhanced Efficiency

Unique formulation achieves “rapid surface drying + instant hardening upon cooling.” Ideal for multi-layer processes requiring quick demolding or stacking, significantly reducing overall production time.

3. Low Odor for a Healthier Creative Environment

Optimized monomer and additive system maintains high performance while drastically reducing volatile odors during operation, providing a more comfortable and healthier workspace for hobbyists and studios.

4. Process Advantages from Higher Viscosity (1900±300 mPa·s)

Medium-high viscosity offers excellent “resin holding” capability on vertical surfaces or complex 3D structures, minimizing drips. Perfect for applications requiring shape retention like resin doming, 3D edging, and cloisonné art.

5. Excellent Material Compatibility & Bonding Strength

Demonstrates superior adhesion (tensile strength ≥20MPa) to various common materials like glass, crystal, acrylic, metal, and ceramic. Ideal not only for encapsulation but also for structural bonding of transparent parts.

6. Clear Power-Time Guidance for Precise Operation

Technical data provides clear curing time references for three common UV lamps (6W, 24W, 72W), enabling users to precisely control the process based on their equipment. Predictable results reduce trial and error.

Detailed Technical Specifications

| Property | 1121-27N3 |

| Color | Light blue transparent liquid |

| Composition | Single-component |

| Viscosity(25℃) | 1900 ± 300 mPa·s |

| Curing Time(25℃) | 6W Lamp: 2 min/side, 72W Lamp: 1 min/side |

| Tensile Strength | ≧20 |

| Hardness(shore D) | 85 |

| Shelf Life | 2 Years |

Usage Guide & Steps

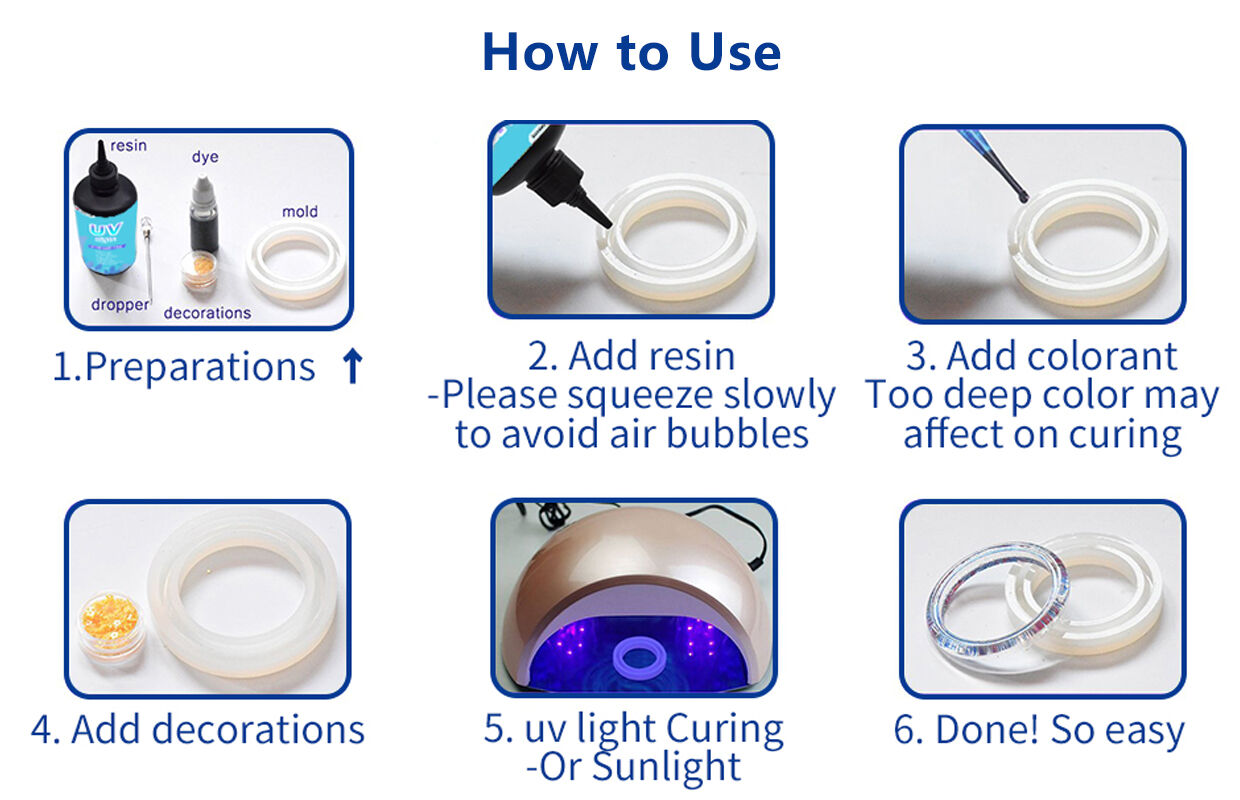

1.Preparation: Prepare UV resin and necessary tools (mold, UV lamp, measuring cup, stirring stick, color pigments, etc.

2.Measure And Dispense Adhesive: Estimate the required amount based on mold size, and evenly dispense UV resin into the measuring cup.

3.Add Color (Optional): If coloring is desired, add a small amount of color pigment or paste.

4.Mix Thoroughly: Stir the resin and color pigment thoroughly to achieve a uniform mixture, avoiding bubble formation.

5.Pour Into Mold: Slowly pour the mixed resin into the mold, ensuring even filling and no overflow.

6.UV Cure: Place the mold under the UV lamp and expose each side for 2–3 minutes until fully cured.

7.Demold And Complete: Once fully cured, gently demold to reveal a crystal-clear finished piece.

Helpful Tips

Things to Note

Storage And Shelf Life

Applications & Project Gallery

Scenario 1: Creation and Restoration of High-End Crystal & Glass Crafts

Scenario 2: Creative Resin Crafts & Permanent Botanical Preservation

Scenario 3: Fusion of Traditional Craftsmanship & Modern Design Protection

Scenario 4: DIY Home Décor & Personalized Customization

Scenario 5: Model Making & Creative Prototype Encapsulation

OEM Customization Service

1.Customized formulation: Viscosity, flowability, curing time, hardness, transparency, color, and various functional additives (anti-yellowing, UV resistance, flexibility enhancement, flame retardancy, etc.) can be adjusted according to needs to meet different industry application scenarios.

2.Packaging Customization: Multiple packaging sizes are available to suit your production scale, including 1kg, 5kg, 20kg, 25kg, and 200kg drums. All packaging follows international shipping standards to ensure safety and durability.

3.Private Label: Supports brand customization, including bottle label design, outer packaging printing, and logo labeling, helping brand owners and wholesalers quickly build their own brands and enter the market.

4.Supplies and Kits: Pre-mixed kits (such as resin + resin pigment + mold + tools, etc.) are provided according to your end product.

5.Color matching and functional additives: Color matching services are supported, and special effects such as metallic, transparent, and pearlescent colors can be added, as well as various functional additives such as UV stabilizers, defoamers, scratch and abrasion resistant agents, and flame retardants.

6.Sample support: We support sample orders for performance testing before mass production. This ensures compatibility with your process, equipment, and application requirements.

7.Technical consultation and process guidance: Engineers provide one-on-one technical guidance on construction suggestions, curing conditions, mixing ratios, application processes, etc., to help you solve practical problems.

Why Choose Our Customization Services?

1.Fast Response — Initial Technical Proposal Within 72 Hours

Once we receive your requirements, our engineering team will provide an initial formulation direction or technical recommendation within 72 hours. This significantly shortens your R&D cycle and speeds up time-to-market.

2. Cost Advantage — 15–30% Lower Than Trading Companies

As a factory with no middlemen, we offer highly competitive OEM pricing while maintaining strict quality standards. Ideal for distributors, factories, and brand owners seeking stable and scalable supply.

3. Confidentiality Guaranteed — 100% NDA Support, Formulations Never Disclosed

Every custom project can be secured with an NDA. We protect your formulations, data, and intellectual property with strict confidentiality standards and never share them with third parties.

4. End-to-End Control: One-Stop Service from Raw Materials to Delivery

Full in-house control over formulation, production, filling, private labeling, packaging, and logistics ensures consistent quality and stable supply.

5. 17+ Years of Material Manufacturing Expertise

With deep expertise in epoxy resin, PU resin, UV resin, liquid silicone rubber, and gypsum powder, we understand the performance needs of various industries including electronics, crafts, automotive, LED, molds, and flooring.

6.Technical Core: In-House R&D Center and Engineering Team

Experienced application engineers provide one-on-one support in formulation tuning, process optimization, and troubleshooting to ensure optimal performance.

7. Stable Quality — ISO9001 Certified Production

We follow strict quality control standards under ISO9001:2015. Every batch is traceable, stable, and tested to meet your specifications.

8. Fast Sampling & Flexible MOQ

We support rapid sample production and low-MOQ orders, reducing risks for new product launches, distributors, and factory procurement.

9. Brand Empowerment: Complete Private Label and Packaging Customization

Full white-label services including label design, multi-size packaging, and brand logo printing to help you build a professional brand image with ease.

10.Global Delivery: Scalable Production and International Logistics Network

Own large-scale production facilities paired with a mature global logistics network ensure stable output and on-time delivery worldwide.

If You Need Customized Packaging Or Other Specifications, Please Contact Us.

FAQ:

1.Q: Is there really such a big difference between 72W and 6W UV lamp curing times?

A: Yes, higher power lamps cure faster. 1 minute with 72W vs. 2 minutes with 6W per side.

2.Q: What is the maximum pouring thickness?

A: Recommended max 3mm per layer. Thicker pieces require layered pouring and side lighting.

3.Q: Why is the surface still tacky after curing?

A: Likely due to insufficient UV lamp power or exposure time. Use a higher power lamp or extend exposure.