Ultra-Thin Self-Leveling Epoxy Resin for Stickers and Badges

Model: 1201AB-LX2 Mix Ratio: By Weight 1.2:1

Key Features:

- Flexible Yet Durable - Maintains moderate flexibility after curing.

- 1:1 Easy Mix Ratio - Equal volume mixing for simple operation.

- Fast Initial Cure - Surface cure in 5-6 hours, reducing wait time.

- 3X Yellowing Resistance - 3 times more resistant than standard epoxy.

Technical Specifications:

| ☆ 3x Yellowing Resistance | ☆ Pot Life: 25±5 min |

| ☆ Hardness: Shore D 82±2 | ☆ Volume Ratio: 1:1 |

Perfect For:

| ☆ High-Value Craft & Specimen Preservation | ☆ Premium Signage & Nameplate Coating |

| ☆ LED Lighting & Display Protection | ☆ Badge & Medal Professional Coating |

| ☆ Flexible Electronics Protection | ☆ Precision Component Potting |

- Overview

- Recommended Products

-

Flexible Protection Advantage: Specifically formulated for delicate surfaces and flexible substrates. Maintains moderate flexibility after curing, avoiding brittleness issues of traditional epoxy. Protects LED strips and flexible circuits without cracking from bending, extending product lifespan.

-

Optical Performance Optimization: 92%+ light transmission with crystal clarity maximizes preservation of original colors and details. Ideal for LED strips, crystal crafts, colored signage, and other applications demanding high optical performance.

- User-Friendly Operation: 1:1 volume mixing ratio greatly simplifies operation, reducing mixing errors. Self-degassing formula minimizes post-processing. Moderate viscosity (2000±300mPa·s) enables precise, controllable application.

-

Safety First: Operate in a well-ventilated area, away from ignition sources. Avoid skin and eye contact.

-

Mix as Needed: Estimate quantity based on the 40-minute pot life to avoid waste.

-

Adapt to Conditions: Preheat Component A if temperature <15°C; use heat-assisted curing if humidity >85% to prevent surface whitening.

- Safe Keeping: Keep out of reach of children.

-

Storage Conditions: Store in a cool, dry place below 25°C (77°F). Keep away from direct sunlight, heat sources, and humid environments.

- Packaging & Stability: The product has a shelf life of 6 months from the date of manufacture when stored unopened in its original container under recommended conditions. Once opened, reseal tightly and use as soon as possible. Do not leave exposed to air for extended periods.

-

For: LED strip lights, neon signs, decorative lighting encapsulation.

- Key Benefits: 92%+ light transmission maintains brightness, flexibility prevents cracking during installation, 3x yellowing resistance ensures long-term clarity.

-

For: Crystal specimens, dried flower art, mineral sample encapsulation.

- Key Benefits: Crystal clarity reveals fine details, moderate flexibility prevents damage from vibration, self-degassing ensures flawless surfaces.

- For: Acrylic signs, metal nameplates, storefront signage protection.

- Key Benefits: Enhances surface hardness to Shore D 82, scratch and weather resistant, maintains clarity outdoors without yellowing.

-

For: Commemorative badges, employee ID tags, promotional pins.

- Key Benefits: Provides flexible protective layer, durable against daily wear, high gloss elevates product quality.

-

For: Flexible printed circuits (FPC), wearable devices, curved sensors.

- Key Benefits: Moderate flexibility accommodates bending, excellent insulation protects circuits, good thermal dissipation.

-

For: Small sensors, communication modules, control unit encapsulation.

- Key Benefits: 2000±300mPa·s optimal viscosity ensures thorough filling, flexibility relieves thermal stress, protects delicate components.

-

For: Resin pour art, epoxy jewelry, creative coaster top coating.

-

Key Benefits: 1:1 equal volume ratio simplifies mixing, self-degassing reduces rework, high transparency enhances color vibrancy.

- For: Furniture surface coating, decorative panel protection, creative home accessories.

- Key Benefits: Food-contact safe eco formula, easy-clean surface, maintains aesthetic appeal over time.

Professional Epoxy Resin Manufacturing Experts

Shenzhen Jianghe New Materials Technology Co., Ltd. is a leading developer and manufacturer of high-performance polymer materials, including epoxy resin, PU resin, UV resin, and liquid silicone rubber. As an integrated source factory combining R&D, production, and sales, we operate a 20,000㎡ modern production base in Dongguan, certified with ISO9001 and other international standards. Supported by advanced equipment, a dedicated R&D team, and a strict QC system, we deliver over 25,000 tons of stable, high-quality, and cost-effective products annually to clients in over 100 countries. We specialize in customized formulations and OEM/ODM services, empowering industries from crafts and furniture to electronics and composites with reliable material solutions.

Key Advantages & Features

Highlight 1: Breakthrough Yellowing Resistance Technology

Utilizing patented anti-yellowing formulation with 3 times the yellowing resistance of standard epoxy. Maintains long-term clarity even under strong light exposure, ideal for decorative and display applications requiring high color stability.

Highlight 2: Exceptional High Temperature Tolerance

Heat deflection temperature up to 90°C, suitable for long-term use in high-temperature environments without softening or deformation. Ideal for automotive electronics, outdoor equipment, kitchenware, and other high-temperature applications.

Highlight 3: Dual Suitability for Decorative & Industrial Use

Unique formulation meets both aesthetic requirements for decorative use (high gloss, ripple-free) and performance requirements for industrial applications (high strength, heat resistance, insulation). One resin for multiple uses, simplifying procurement and management.

Highlight 4: Professional Flexible Encapsulation Solutions

Detailed Technical Specifications

| Property | Part A | Part B |

| Color | Colorless Transparent | Colorless Transparent |

| Density (g/cm³) | 1.15±0.05 | 0.95±0.03 |

| Viscosity (mPa·s) | 8500±1000 | 1200±400 |

| Mix Ratio (By Weight) | A : B=1.2:1 (weight ratio) | |

| Pot Life (100g, 25°C) | 20±5 min | |

| Viscosity After Mixing | 2000±300mPa.S | |

| Surface Dry | 5-6 hours | |

| Full Cure | 36-48 hours | |

| Hardness (Shore D) | 82±2 | |

| Water Absorption (%) | <0.1 | |

| Shelf Life | 6 months | 6 months |

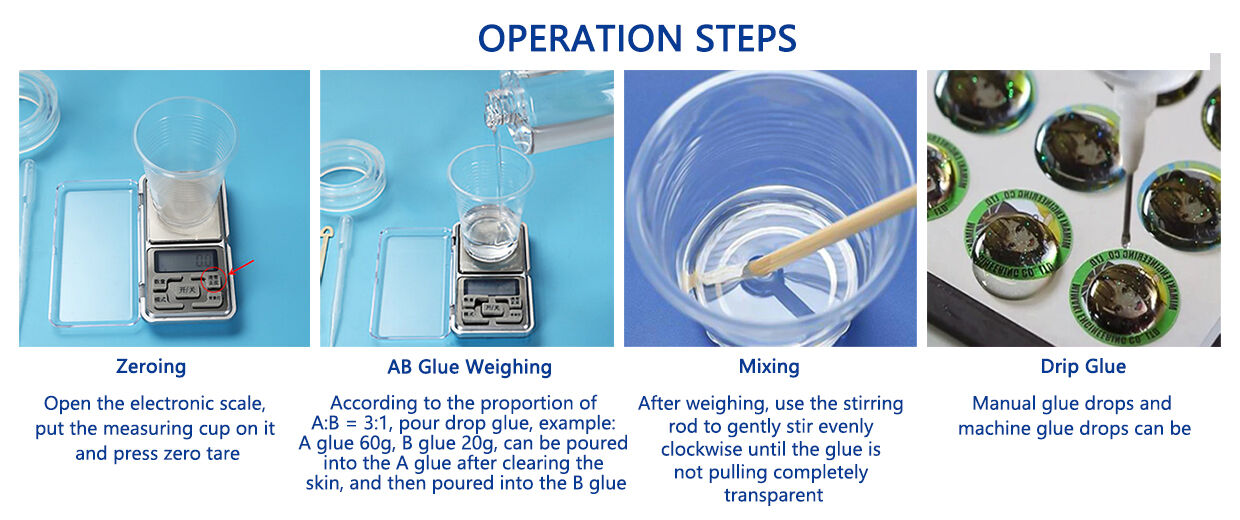

Usage Guide & Steps

1.Accurate Measurement: Measure accurately at 1.2A:1B weight or 1:1 volume ratio.

2.Thorough Mixing: Stir clockwise 3-5 mins until fully homogeneous, scrape container walls.

3.Rest & Debubble: Let stand 3-5 mins for self-debubbling, vacuum degas if needed.

4.Quick Application: Complete pouring or coating within 25±5 min pot life.

5.Curing: Initial cure 5-6 hrs@RT, full cure 36-48 hrs@RT.

Safety, Handling & Storage Guidelines

1. For Safe Operation & Mixing

2.Storage And Shelf Life

Applications & Project Gallery

LED Lighting & Display Protection

High-Value Craft & Specimen Preservation

Premium Signage & Nameplate Coating

Badge & Medal Professional Coating

Flexible Electronics Protection

Precision Component Potting

Professional Artists & Makers

Home Décor Enhancement & Protection

OEM Customization Service

1.Customized formulation: Viscosity, flowability, curing time, hardness, transparency, color, and various functional additives (anti-yellowing, UV resistance, flexibility enhancement, flame retardancy, etc.) can be adjusted according to needs to meet different industry application scenarios.

2.Packaging Customization: Multiple packaging sizes are available to suit your production scale, including 1kg, 5kg, 20kg, 25kg, and 200kg drums. All packaging follows international shipping standards to ensure safety and durability.

3.Private Label: Supports brand customization, including bottle label design, outer packaging printing, and logo labeling, helping brand owners and wholesalers quickly build their own brands and enter the market.

4.Supplies and Kits: Pre-mixed kits (such as resin + resin pigment + mold + tools, etc.) are provided according to your end product.

5.Color matching and functional additives: Color matching services are supported, and special effects such as metallic, transparent, and pearlescent colors can be added, as well as various functional additives such as UV stabilizers, defoamers, scratch and abrasion resistant agents, and flame retardants.

6.Sample support: We support sample orders for performance testing before mass production. This ensures compatibility with your process, equipment, and application requirements.

7.Technical consultation and process guidance: Engineers provide one-on-one technical guidance on construction suggestions, curing conditions, mixing ratios, application processes, etc., to help you solve practical problems.

Why Choose Our Customization Services?

1. Fast Response — Initial Technical Proposal Within 72 Hours

Once we receive your requirements, our engineering team will provide an initial formulation direction or technical recommendation within 72 hours. This significantly shortens your R&D cycle and speeds up time-to-market.

2. Cost Advantage — 15–30% Lower Than Trading Companies

As a factory with no middlemen, we offer highly competitive OEM pricing while maintaining strict quality standards. Ideal for distributors, factories, and brand owners seeking stable and scalable supply.

3. Confidentiality Guaranteed — 100% NDA Support, Formulations Never Disclosed

Every custom project can be secured with an NDA. We protect your formulations, data, and intellectual property with strict confidentiality standards and never share them with third parties.

4. End-to-End Control: One-Stop Service from Raw Materials to Delivery

Full in-house control over formulation, production, filling, private labeling, packaging, and logistics ensures consistent quality and stable supply.

5. 17+ Years of Material Manufacturing Expertise

With deep expertise in epoxy resin, PU resin, UV resin, liquid silicone rubber, and gypsum powder, we understand the performance needs of various industries including electronics, crafts, automotive, LED, molds, and flooring.

6.Technical Core: In-House R&D Center and Engineering Team

Experienced application engineers provide one-on-one support in formulation tuning, process optimization, and troubleshooting to ensure optimal performance.

7. Stable Quality — ISO9001 Certified Production

We follow strict quality control standards under ISO9001:2015. Every batch is traceable, stable, and tested to meet your specifications.

8. Fast Sampling & Flexible MOQ

We support rapid sample production and low-MOQ orders, reducing risks for new product launches, distributors, and factory procurement.

9. Brand Empowerment: Complete Private Label and Packaging Customization

Full white-label services including label design, multi-size packaging, and brand logo printing to help you build a professional brand image with ease.

10.Global Delivery: Scalable Production and International Logistics Network

Own large-scale production facilities paired with a mature global logistics network ensure stable output and on-time delivery worldwide.

If You Need Customized Packaging Or Other Specifications, Please Contact Us.

FAQ:

1.Q: How flexible is this epoxy after curing? What's the bending angle?

A: Medium flexibility with Shore D 82±2 hardness. 2mm thick samples can bend 90-120 degrees without cracking, depending on thickness and substrate. It optimally balances protection (scratch/wear resistance) and flexibility.

2.Q: Does flexibility compromise protection performance, like scratch resistance?

A: No compromise on core protection. While flexible, surface hardness remains Shore D 82, providing excellent scratch and wear resistance. It's an optimized solution between rigid protection and complete softness.

3.Q: 1:1 volume ratio vs 1.2:1 weight ratio - which is more accurate?

A: 1:1 volume ratio is recommended for most applications - simpler with smaller errors. For high-precision electronic potting, use 1.2:1 weight ratio. We provide graduated dual-component mixing cups.

4.Q: Is 25±5 minutes pot life enough for complex coating work?

A: 25 minutes is for 100g mixed at 25°C. Extend working time by: ① Mixing in batches ② Reducing ambient temperature to 20°C ③ Using wide, shallow containers for heat dissipation. For large pieces, work in sections.

5.Q: Can fluorescent powder, pigments, or glitter be added? Will it affect performance?

A: Yes, up to 5% pigments or 3% glitter by total weight. Use epoxy-specific pigments and conduct small tests first. Additives may slightly reduce light transmission (2-5%) but won't affect flexibility or protection.