As casting applications continue to expand across furniture, crafts, electronics, and mold-making industries, selecting the right material has become essential for achieving the best performance and durability. Whether you are creating a river table, surface coatings, casting prototypes, electronic potting, or silicone molds, the material you choose will directly affect appearance, strength, efficiency, and long-term stability.

This article provides a clear, professional comparison of Epoxy Resin, PU Resin, and Liquid Silicone, helping you determine the most suitable option for your specific casting project.

1. A Deeper Dive into Each Material

1.1 Epoxy Resin: The Champion of Strength and Adhesion

Epoxy resin cures via an irreversible exothermic reaction between resin and hardener, forming a dense, cross-linked polymer network. This chemistry is the source of its renowned performance.

Advantages:

Limitations & Management:

1.2 PU Resin: The Star of Clarity and Speed

PU resin cures by reacting with atmospheric moisture or a separate hardener, creating polymers that can range from soft elastomers to hard plastics. Its urethane linkage provides a unique balance of properties.

Advantages:

Limitations & Management:

1.3 Liquid Silicone Rubber: The Mother of Molds, The Perfect Elastomer

Liquid Solicone Rubber cures via a platinum or tin-catalyzed addition reaction, forming a silicone-oxygen backbone that is inherently stable and inert.

Advantages:

Limitations & Management:

2. Side-by-Side Performance Comparison

| Property | Epoxy Resin | PU Resin | Liquid Silicone Rubber |

| Hardness & Strength | Very High, Rigid | Wide Range, Soft to Hard | Soft, Flexible |

| Flexibility | Poor, Brittle | Good | Excellent |

| Yellowing Resistance | Fair (requires UV-resistant grade) | Excellent (especially aliphatic) | Excellent |

| Heat Resistance | Moderate | Moderate | Very High (up to 250°C+) |

| Curing Method | Hardener, Slow or Fast | Moisture Cure, Fast | Platinum or Tin Cure, Heat or RT |

| Shrinkage | Low | Moderate | Very Low |

| Primary Applications | River Tables, Flooring, Potting | Surface Coating, Rapid Prototyping | Mold Making, Food-Safe Items |

3.How to Choose? A Decision Guide Based on Your Application

3.1 For River Tables or Thick Transparent Castings

➡ Choose Epoxy Resin

Why: Deep-pour, slow-cure epoxy formulations are engineered for minimal exotherm, preventing cracking in thick sections. Their low shrinkage ensures the resin = remains perfectly bonded to the wood without unsightly gaps. For tables near sunlight, specify UV-stabilized, non-yellowing aliphatic epoxies.

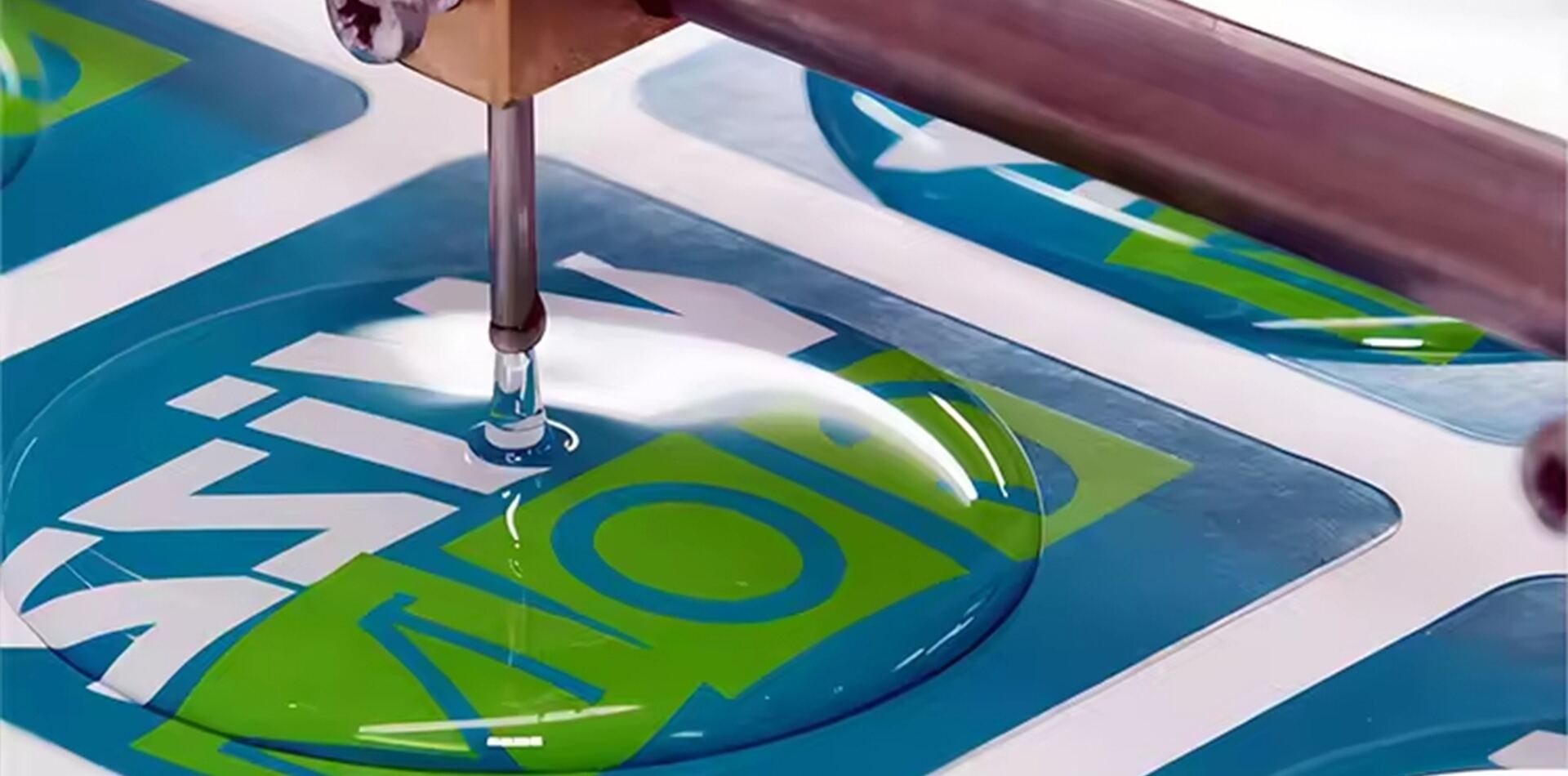

3.2 For Surface Doming Badges, Stickers, or High-Efficiency Production

➡ Choose PU Resin

Why: Fast cycle time is paramount. PU’s rapid cure and easy demolding accelerate production. Its inherent clarity and color stability guarantee every piece meets aesthetic standards without yellowing. For efficiency, use a meter-mix-dispense system tailored to the resin’s pot life.

3.3 For Mold Making Across Crafts, Replicas, and Small Production

➡ Choose Liquid Silicone

Why: Liquid Silicone Rubber exceptional tear strength and <0.1% shrinkage allow you to demold intricate, undercut geometries without damaging the master or the mold. The resulting mold will faithfully produce dozens of identical casts. For large masters, a low-viscosity, high tear-strength grade is optimal.

3.4 For Electronic Potting or LED Strip Encapsulation

➡ Decision Path:

Choose Epoxy if ultimate moisture sealing, rigidity, and long-term dielectric stability are the priorities.

Choose PU if the assembly may experience thermal cycling or slight flexing, requiring a material with higher elongation to prevent cracking.

4.Beyond Selection: Partnering for Optimized Solutions

Choosing the correct material category is only the beginning. Fine-tuning the formulation is where true optimization occurs—a process that distinguishes a generic product from a superior one.

As your source factory and OEM partner, we provide more than just three material types. We provide engineered solutions:

Take Action Now, Get Your Custom Solution!

If you still have questions about material selection or wish to get a customized product formula for your specific project, please do not hesitate to contact our technical support team or request free samples. Let our expertise and reliable products ensure the success of your project!

Ready to Choose the Right Material? Get Expert Support Today.

Hot News

Hot News2025-12-29

2025-11-25

2025-11-23

2025-11-22