Introduction

Liquid Silicone Rubber (LSR) has revolutionized mold making, offering unparalleled fidelity in detail reproduction, exceptional thermal stability (up to 250°C), and the durability for hundreds of casting cycles. It is the cornerstone material for applications ranging from intricate jewelry and sculpture replication to food-grade chocolate molds and high-temperature resin casting.

However, the journey from liquid silicone to a perfect mold is fraught with potential pitfalls. Issues like micro-bubbles obscuring fine details, incomplete curing leading to sticky surfaces, or premature mold tearing can halt production, waste valuable materials, and compromise project timelines. These problems often stem not from the material itself, but from gaps in process understanding.

This guide delves beyond surface-level tips, providing a deep-dive into the root causes and professional-grade solutions for the five most persistent challenges in LSR mold making. By mastering these principles, you can consistently produce studio-quality molds that enhance your production efficiency and end-product quality.

1. Excessive Air Bubbles in the Mold

Trapped air is the most common enemy of optical clarity and surface perfection, appearing as unsightly voids that can obscure fine textures and create weak points in the mold structure.

Root Caue Analysis:

- Mechanical Entrapment: Vigorous or improper mixing (whipping rather than folding) introduces millions of micro-bubbles.

- Substrate Outgassing: Porous master models (e.g., 3D prints, wood, plaster) contain air that is displaced by the silicone, rising into the mixture.

-

Viscosity Misalignment: Using a silicone that is too viscous for the geometry prevents air from rising to the surface before gelation.

Professional Solutions & Techniques:

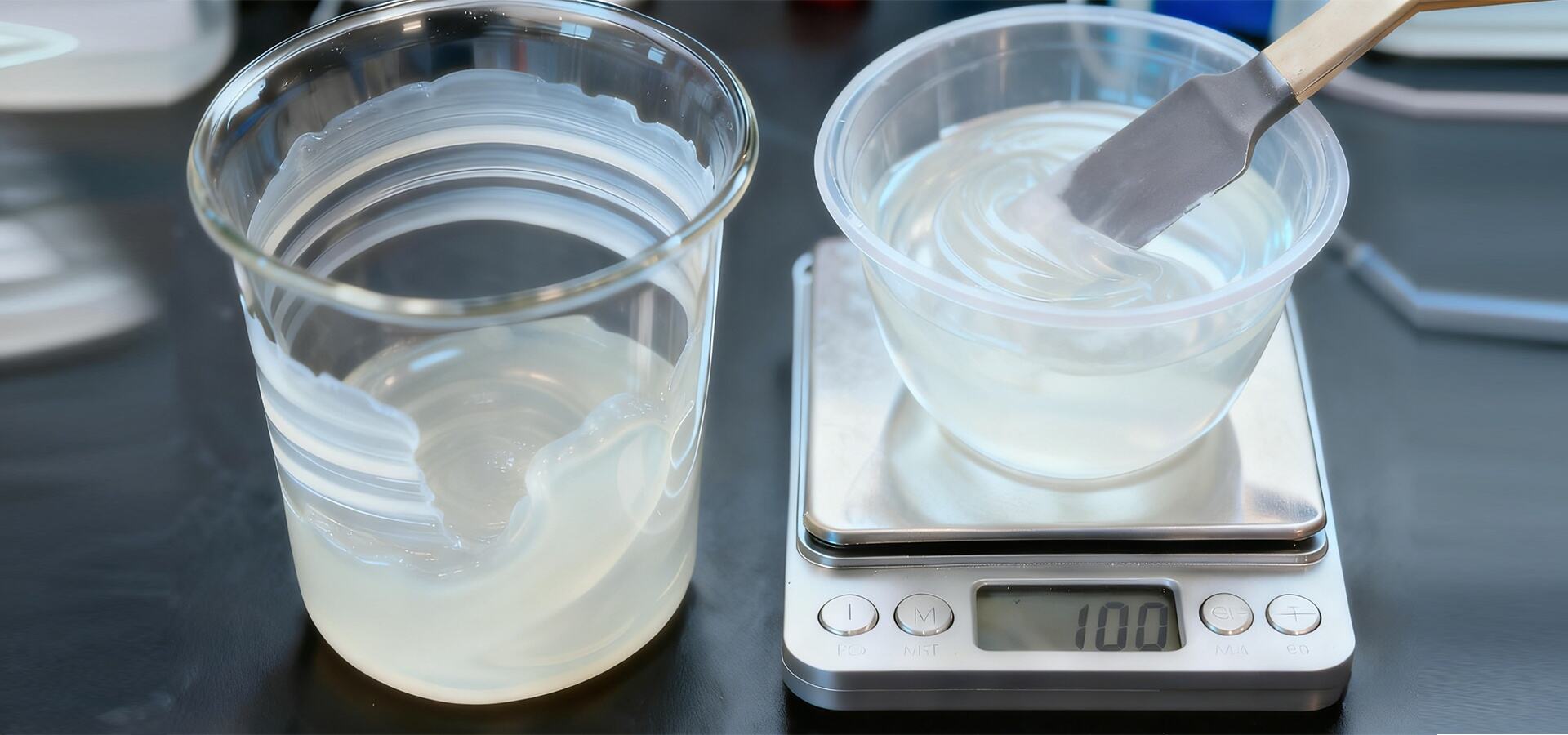

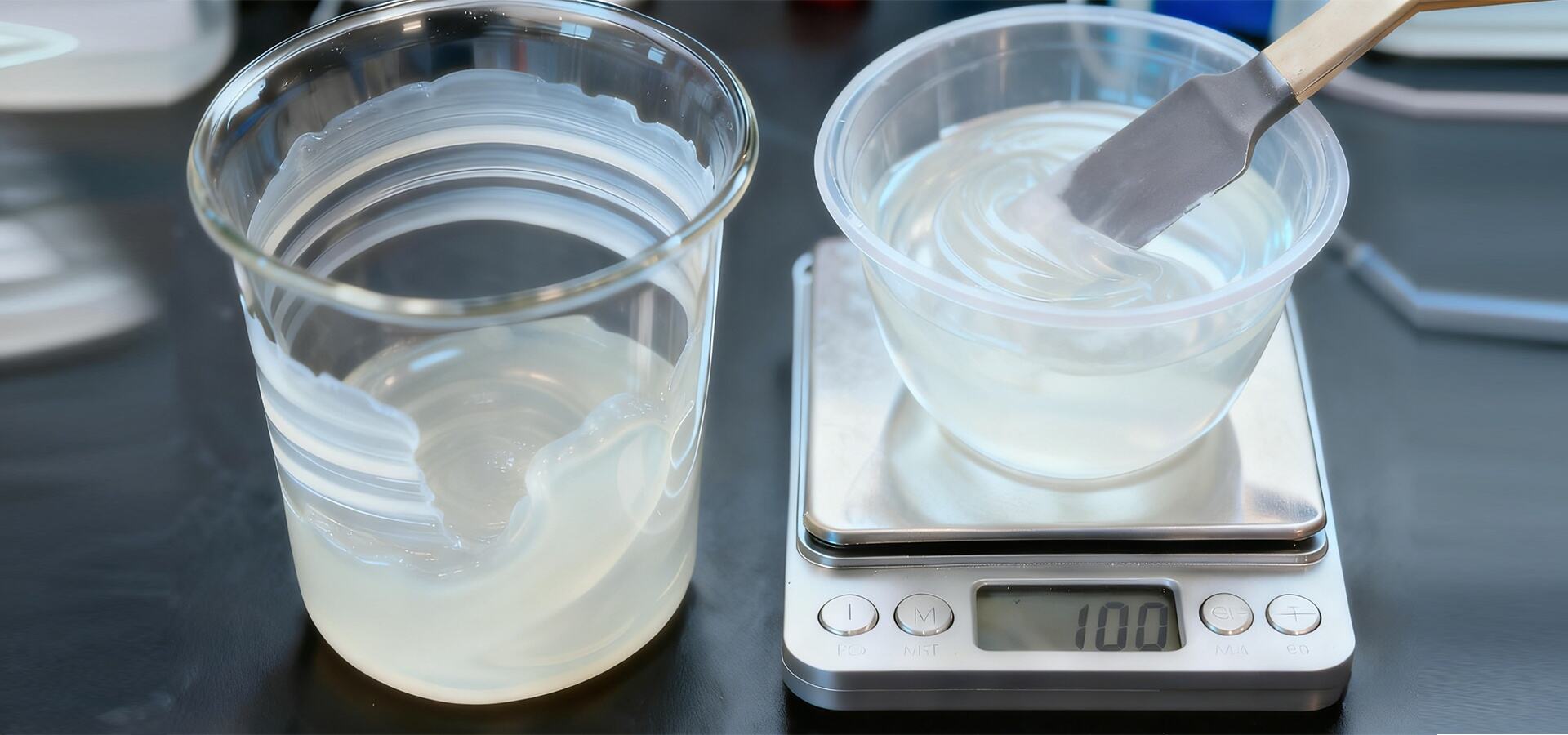

- Two-Stage Pouring & Brush Coating: For highly detailed masters, first mix a small batch of very low-viscosity silicone (e.g., 3,000 mPa·s). Brush or spray a thin layer onto the model, ensuring it penetrates every crevice and pushes out air. This "detail coat" can be partially gelled before pouring the thicker, bulk fill.

- Controlled Vacuum Degassing: Simply placing mixed silicone in a vacuum chamber is not enough. The key is to gradually reduce pressure to allow bubbles to expand and rise without causing the mixture to violently boil over. Hold at full vacuum (typically -29 inHg) until the bubble stream ceases, which may take 2-5 minutes depending on volume.

-

Strategic Pouring: Pour from a significant height into a single, low point of the containment box. This creates a thin, continuous stream that stretches and bursts bubbles as it falls. Let the silicone flow naturally across the master; do not pour directly onto intricate areas.

Need a low-viscosity, bubble-resistant silicone for complex masters? Explore our High-Flow Platinum Series.

2.Incomplete Curing or Significantly Extended Cure Time

When silicone remains tacky or fails to cure in spots, it’s often a chemical issue rather than a mixing one. This is especially critical with platinum-cure silicones, prized for their zero shrinkage and food safety.

Root Cause Analysis:

- Chemical Inhibitors: Sulfur (in some clays and rubbers), tin (from other RTV products), amines (in epoxy hardeners, some paints), and certain plastics (PVC, PET) can poison the platinum catalyst, stopping the reaction at the contact surface.

- Environmental Factors: Temperatures below 20°C dramatically slow the reaction kinetics, while excessive humidity can interfere with condensation-cure (tin-based) systems.

Professional Solutions & Techniques:

1.The Isolation Barrier Test: If you suspect your master model contains inhibitors, apply a universal barrier coat. Options include:

- Acrylic Spray Sealers (multiple light coats)

- Shellac (for organic materials)

- Specialized Inhibitor-Resistant Primer

- Allow the barrier to fully cure (24+ hours) before mold making.

2.Material Selection as a Solution: For consistently problematic masters (e.g., certain 3D resins), switch to a tin-cure (condensation-cure) silicone. While it has higher shrinkage, it is vastly more resistant to chemical inhibition.

3.Process Control: Maintain a warm, stable curing environment (25-30°C) using a temperature-controlled cabinet or space heater. Never accelerate cure with excessive heat, which can cause cracking. Ensuring accurate ratio and adequate mixing is the key to achieving a fully cured, durable mold.

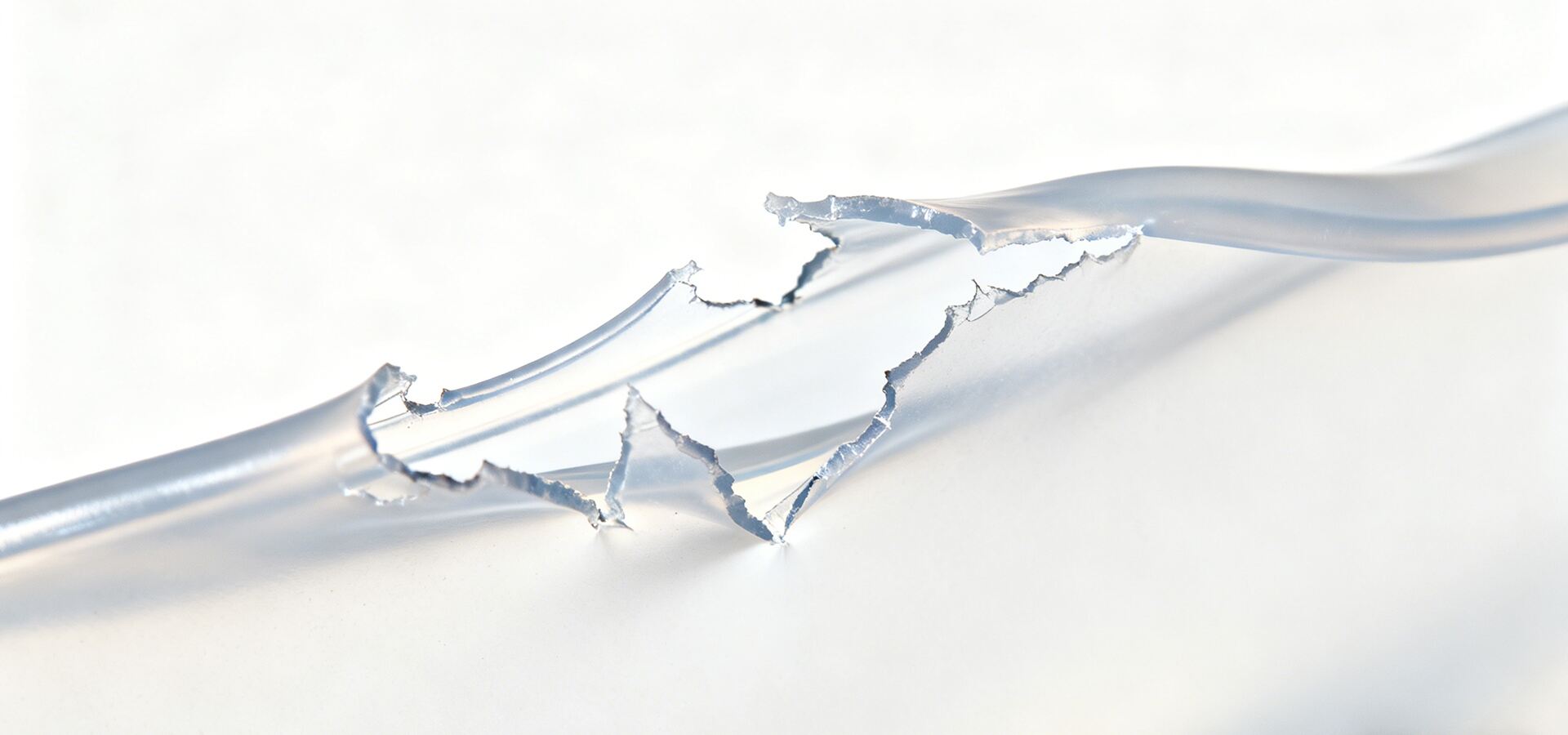

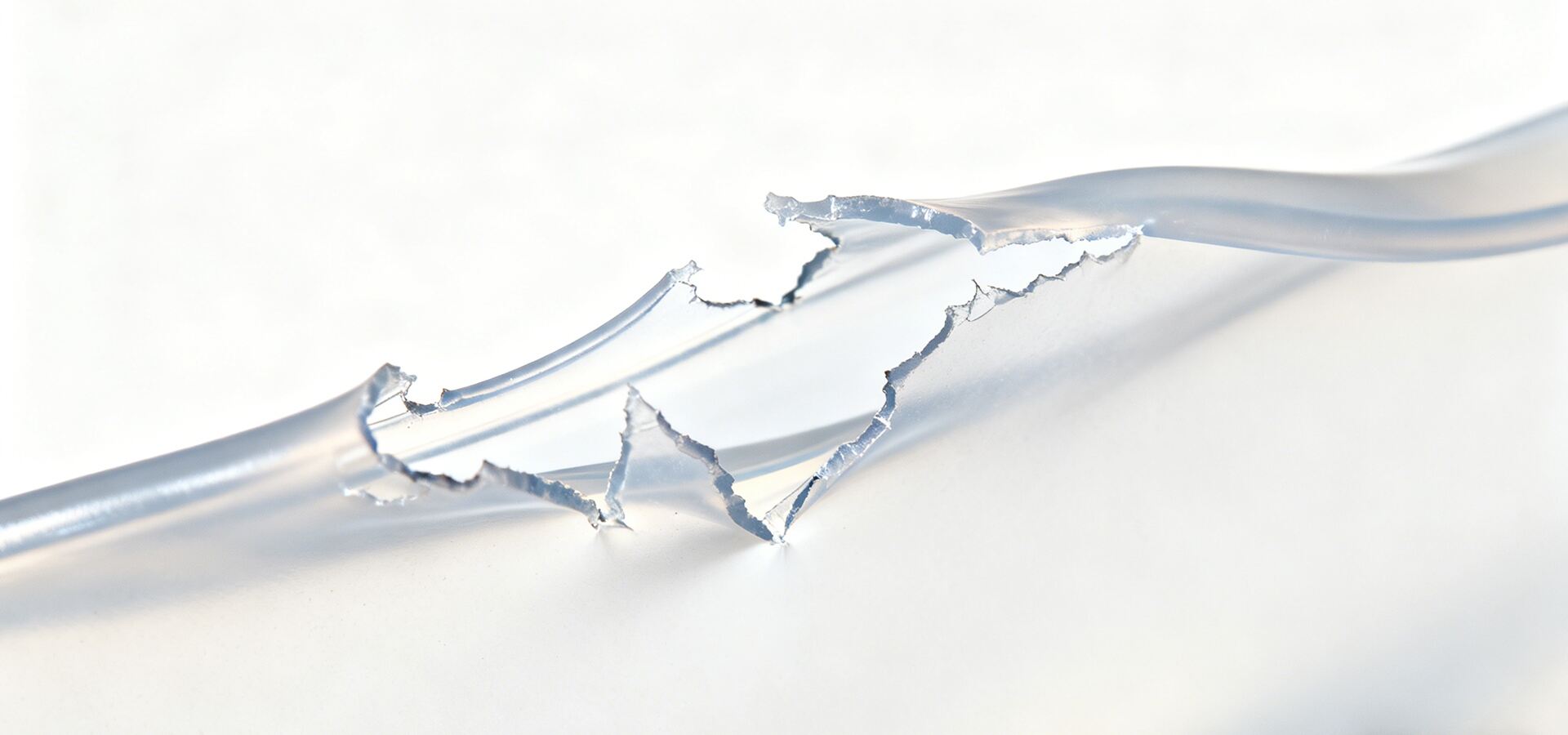

3.Mold Tearing or Short Mold Life

A mold that tears after a few uses undermines production efficiency and increases per-unit cost.

Root Cause Analysis:

- Wrong hardness (Shore A) chosen for the project;

- Walls of the mold are too thin;

- Excessive force during demolding;

- Frequent use without proper cleaning or maintenance;

Professional Solutions & Techniques:

Select the correct hardness:

- Shore A 20–30 for complex or highly detailed molds.

- Shore A 30–40 for large, simple molds.

- Ensure the mold wall thickness is between 5–15 mm;

- Use mold release agents to reduce friction and stress;

- Clean, dry, and properly support molds after each use;

Choosing the right hardness and ensuring proper support can greatly extend mold lifespan.

4. Mold Deformation or Surface Indentations

A mold that produces parts slightly smaller or warped is often useless for functional assemblies.

Root Cause Analysis:

- Movement or vibration during curing;

- Removing the mold before it is fully cured;

- Soft or flexible master models that deform under silicone weight;

- Uneven curing temperatures;

Professional Solutions & Techniques:

- Heat Management for Thick Molds: For blocks thicker than 4cm, use a silicone formulated for deep sections (slower cure, lower exotherm). Pour in layers (2-3cm thick), allowing each layer to gel before adding the next to dissipate heat.

- Mandatory Post-Curing: After demolding at the recommended time, perform a controlled post-cure. Place the mold in a 60-80°C oven for 1-2 hours. This drives the reaction to completion, stabilizes dimensions, and improves tear strength.

- Material Choice is Key: For absolute dimensional fidelity (e.g., engineering prototypes), platinum-cure addition silicones are non-negotiable, offering shrinkage of <0.1%.

Stability during curing is critical to achieving accurate mold dimensions.

5.Mold Sticking or Difficult Demolding

A difficult demolding process risks damaging both the expensive master and the newly made mold.

Root Cause Analysis:

- No mold release applied;

- Incompatible materials (resin, metal, or certain plastics);

- Contaminants such as oils, dust, or uncured coatings;

- Deep undercuts or complex geometry;

Professional Solutions & Techniques:

- Always apply a thin, even layer of mold release before pouring silicone;

- Use sealing wax or a surface treatment to improve release;

- Clean and dry the master model thoroughly;

- For deep undercuts, design the mold with multiple parts or flexible zones;

- Consider using higher-flexibility silicone (lower Shore hardness);

Proper preparation of the master model ensures smooth, repeatable demolding.

Conclusion: Better Material + Better Technique = Better Molds

Liquid silicone is highly versatile and an excellent choice for mold making, but the final results depend heavily on proper mixing, degassing, curing, and demolding methods. By understanding and preventing the common issues above, you can greatly improve mold consistency, detail reproduction, and lifespan.

If you need assistance selecting the right silicone hardness, adjusting curing characteristics, or optimizing your production process, our technical team is ready to help with:

- Material selection guidance;

- Customized hardness and viscosity options;

- Process optimization;

- Free sample testing;

Contact us today for expert support and tailored silicone solutions.

Hot News

Hot News