Epoxy resin is one of the most versatile and reliable materials used across modern industries—from furniture and crafts to electronics, automotive parts, flooring, and signage manufacturing.

Whether you are building a river table, casting DIY molds, coating carbon fiber, or potting LED drivers, choosing the right epoxy resin is essential for performance, durability, and appearance.

This guide will break down everything you need to know—from basic chemistry to selecting the right type for your industrial or creative business needs.

1.What Exactly Is Epoxy Resin?

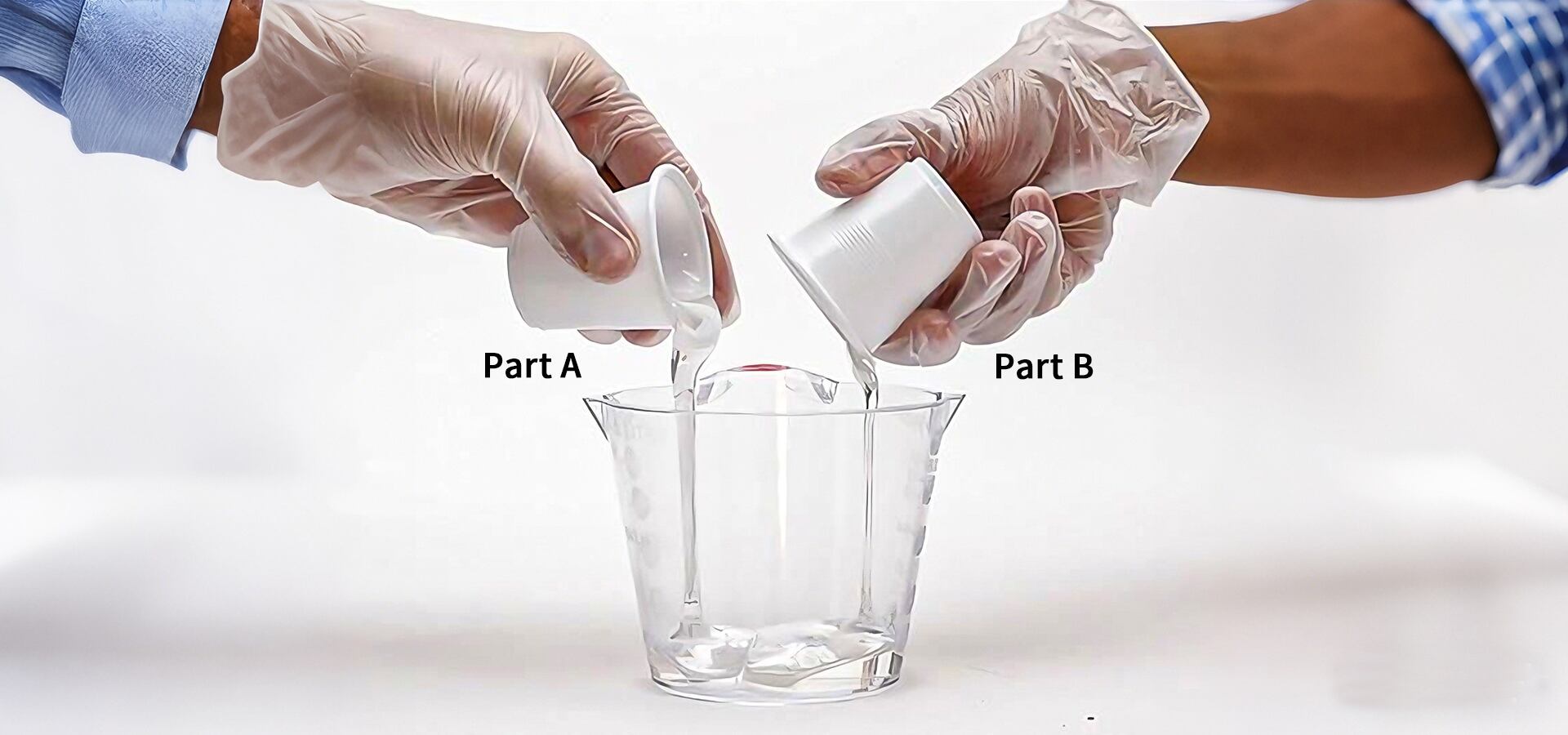

Epoxy resin is a two-part thermosetting polymer consisting of resin (Part A) and hardener (Part B). When mixed at the proper ratio, a chemical reaction occurs—transforming the liquid resin into a solid material with exceptional strength, clarity, and chemical resistance.

Key Characteristics:

2.How Epoxy Resin Works: The Chemistry Behind It

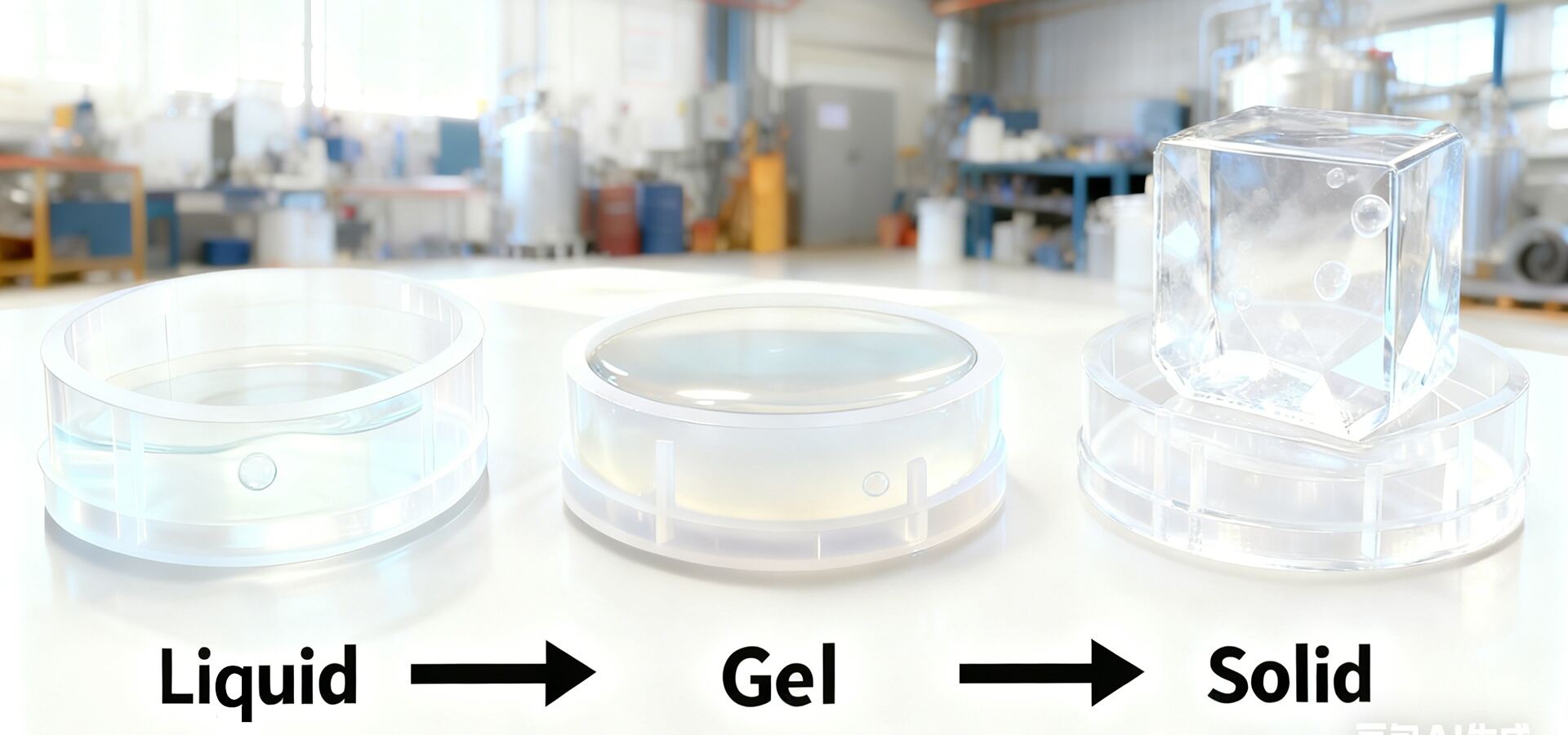

Epoxy resin cures through a process called polymerization. Once mixed, the molecules begin forming crosslinks, turning the mixture from liquid to gel, then to a fully hardened solid.

Three Essential Curing Stages:

3.Common Types of Epoxy Resin

Epoxy resin varies based on application. The most common categories include:

3.1 Deep Pour Casting Resin for Encapsulation & River Tables

Specially designed for 1–18 cm deep pours, ideal for:

Features:

3.2 DIY Casting Resin for Crafts & Models

Applications:jewelry, small molds, keychains, small craft decorations.

Features:

3.3 Fake Water Epoxy (Imitation Water Resin)

High clarity and anti-yellowing formula, ideal for:

Features:

3.4 Epoxy Resin for Surface Coating

Used for:

Features: Creates a super glossy, UV-resistant finish.

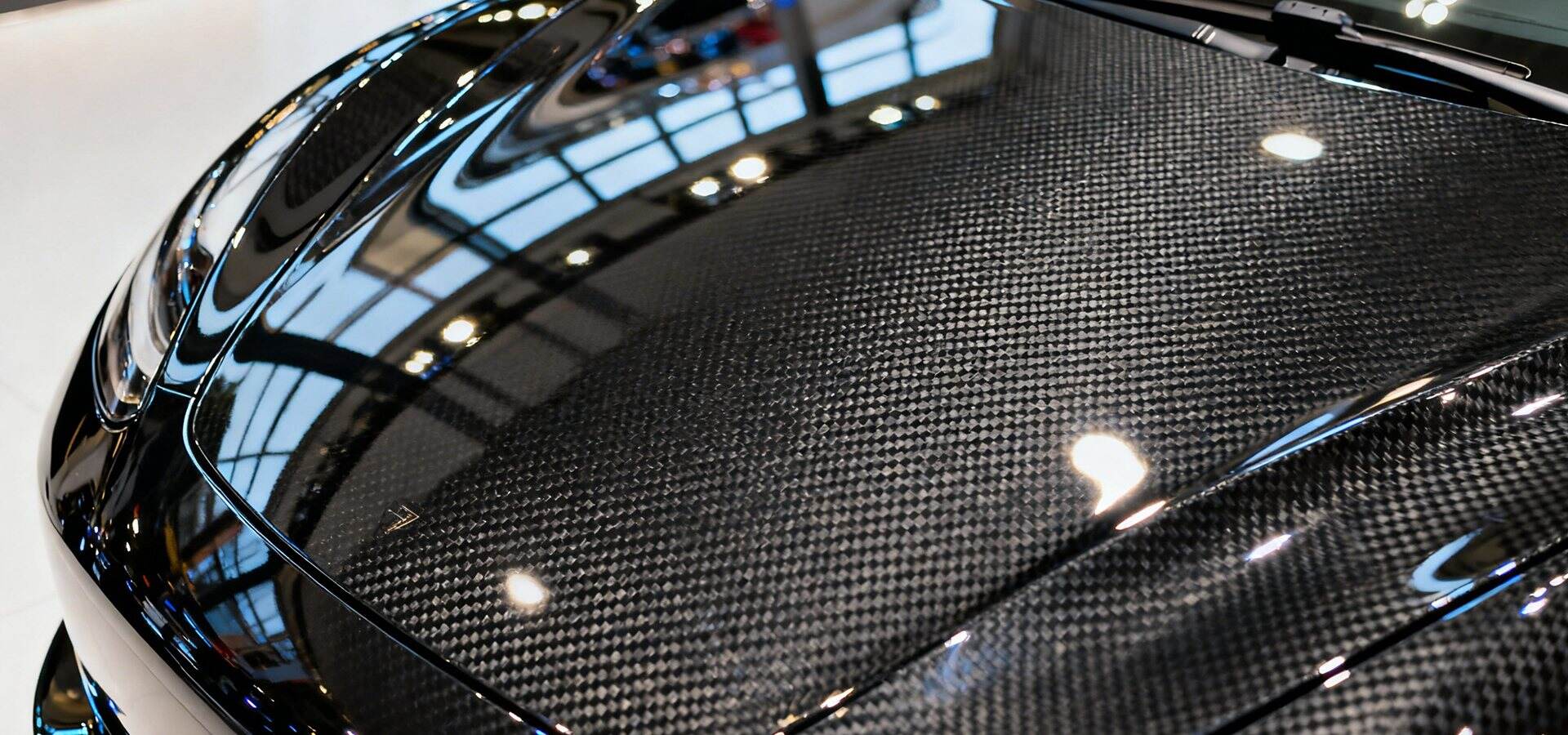

3.5 Epoxy for Carbon Fiber Coating & Polishing

Designed for:

Features: High hardness + excellent heat resistance.

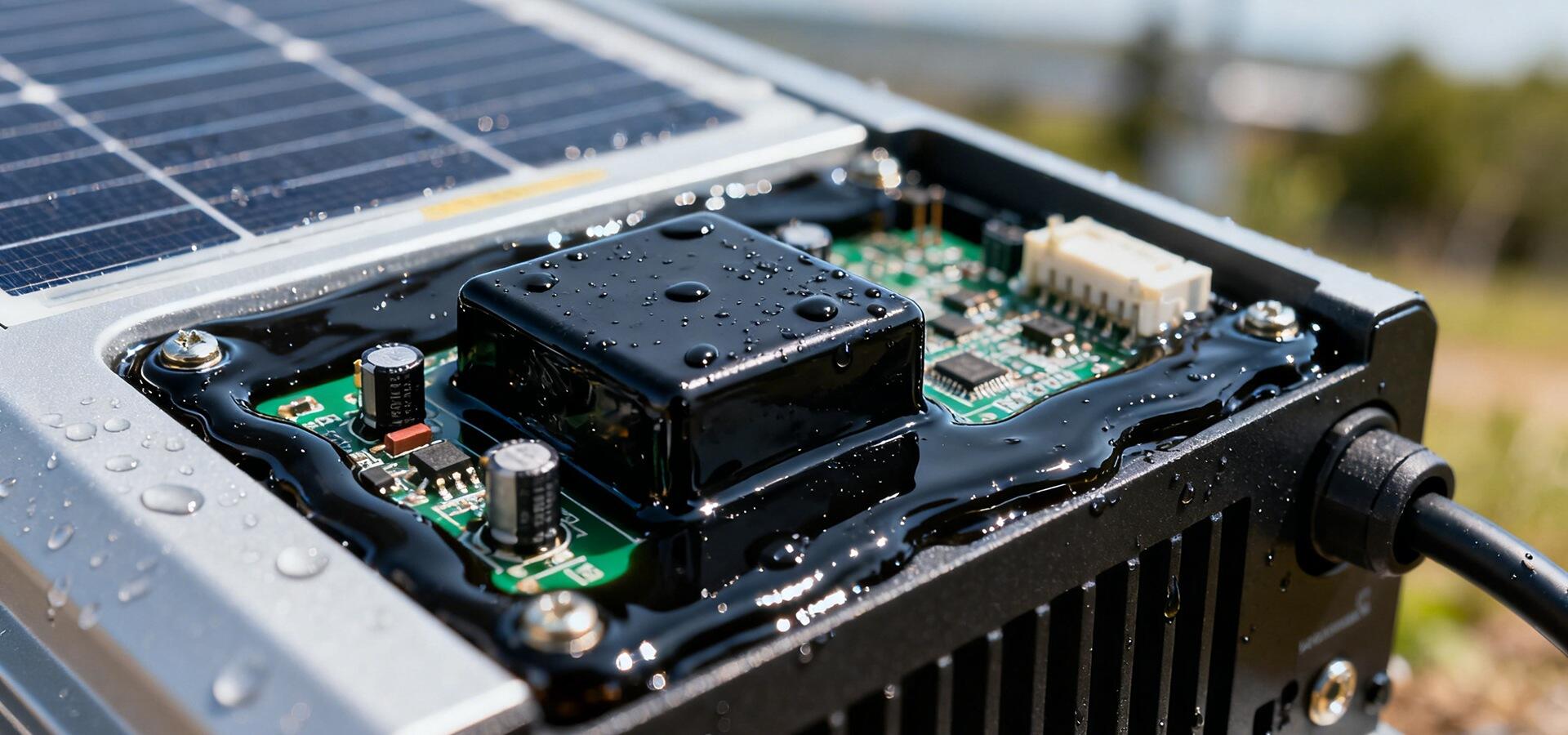

3.6 Industrial Potting Epoxy for Electronics

Used to protect:

Features: Provides insulation, waterproofing, heat resistance.

3.7 Epoxy for LED Channel Letters & Light Strips

Transparent or colored resin for:

Features: Characteristics: anti-yellowing + weather resistance.

3.8 Epoxy Flooring Resin

Used in:

Features: Provides strong adhesion, abrasion resistance, and chemical resistance.

3.9 Epoxy Adhesives (Bonding Grade)

Used for bonding:

Features: Strong structural adhesive for industrial use.

4. How to Use Epoxy Resin: Beginner Steps

Step 1: Measure accurately

Most epoxy requires a 2:1 or 1:1 ratio.

Step 2: Mix slowly and thoroughly

Mix for 2–3 minutes to avoid bubbles.

Step 3: Pour carefully

Pour in thin layers to avoid overheating.

Step 4: Allow to cure

Keep the environment dust-free.

5. Common Problems & Troubleshooting

Beginners often encounter issues such as:

6. Safety Tips for Working with Epoxy

7. Why Choose Us as Your Epoxy Resin Partner

7.1 Factory-Direct Manufacturing & Quality Assurance

With over 17 years of expertise and ISO-certified production, we ensure consistent quality and highly competitive pricing. No middlemen, just reliable supply.

7.2 Tailored OEM/ODM Formulations

Your project is unique. Our R&D team specializes in customizing resins—adjusting flexibility, curing time, UV resistance, and color—to meet your exact specifications.

7.3 Advanced Anti-Yellowing & UV Stability

We integrate premium UV stabilizers and HALS (Hindered Amine Light Stabilizers) into our formulations, guaranteeing long-term clarity and durability for outdoor and display applications.

7.4 One-Stop Portfolio for Diverse Industries

From electronics encapsulation to heavy-duty flooring and artistic casting, we offer a comprehensive range of grades, simplifying your supply chain and ensuring you find the perfect fit.

Epoxy resin is a powerful, versatile, and reliable material across countless industries. Choosing the right type ensures perfect clarity, durability, and long-term performance.

If you need samples, bulk pricing, or custom formulations, our technical team is ready to support your business.

Contact us to get a quote or request free samples.

Hot News

Hot News2026-01-14

2026-01-06

2025-12-27

2025-12-26

2025-12-26

2025-12-25