1. Introduction

Epoxy resin is one of the most versatile polymer materials used across both creative and industrial fields.

From DIY crafts, jewelry, faux water scenes, and resin art → to electronics potting, carbon-fiber coating, industrial flooring, adhesives, epoxy serves two very different worlds.

However, Craft Epoxy ≠ Industrial Epoxy.

For beginners, hobbyists, and industrial buyers, understanding these differences prevents failures, defects, and unnecessary cost.

This guide explains these differences clearly, helping beginners, hobbyists, and professional buyers choose the right formula.

Learn the Basics: What Is Epoxy Resin?

2. What Makes Craft Epoxy Different?

Craft epoxy — often called art resin or DIY resin — is designed for clarity, working time, and easy operation.

2.1 Key Features of Craft Epoxy

2.2 Common Craft Epoxy Applications

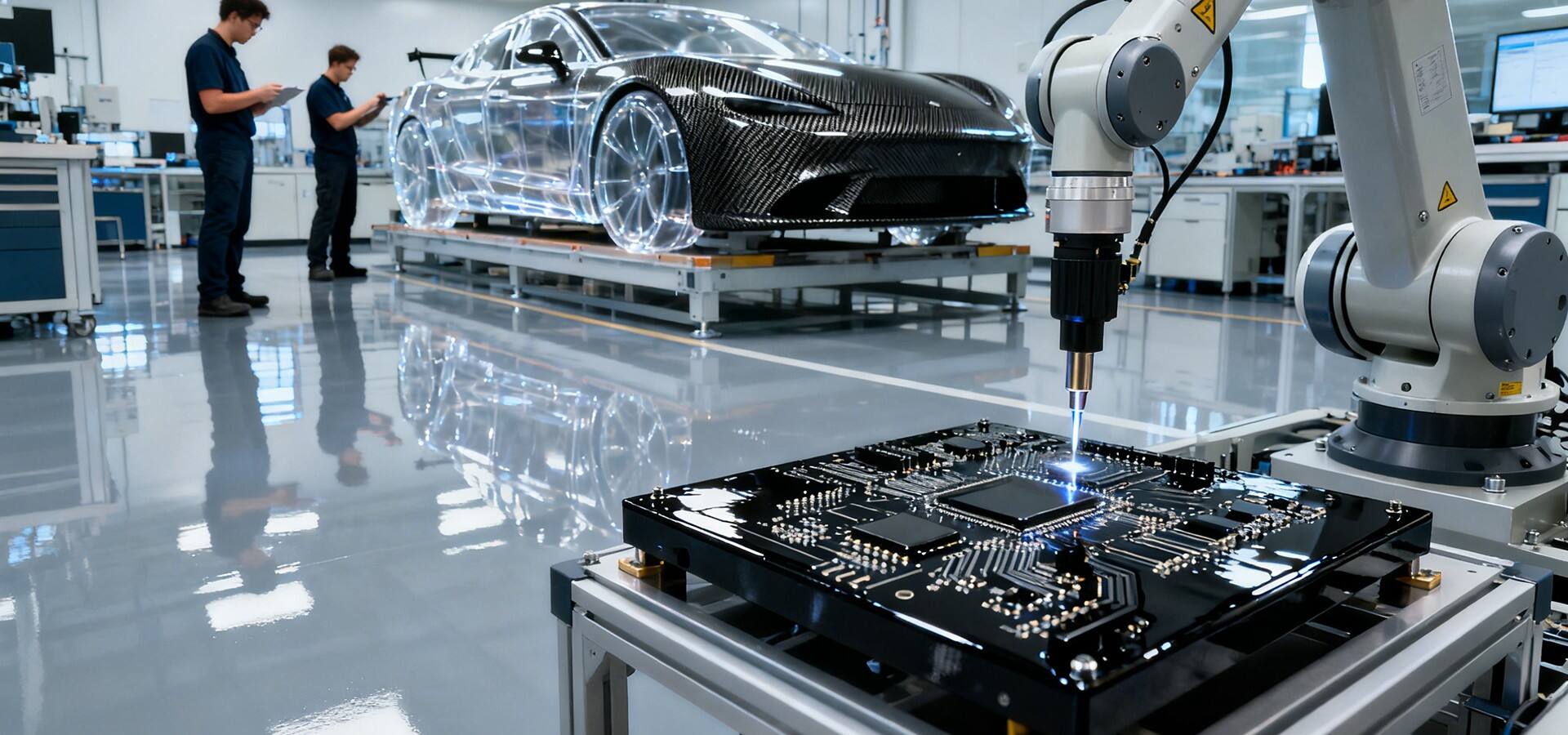

3. What Defines Industrial Epoxy?

Industrial epoxies are engineered for strength, durability, heat resistance, chemical resistance, and production efficiency—not for appearance.

3.1 Key Features of Industrial Epoxy

3.2 Common Industrial Applications

Explore Industrial Epoxy Solutions

4. Craft Epoxy vs. Industrial Epoxy (Side-by-Side Comparison)

| Feature | Craft Epoxy | Industrial Epoxy |

| Clarity | High | Varies (can be opaque or clear) |

| Strength | Moderate | High |

| Heat resistance | Moderate | High |

| Curing speed | Slower | Fast or slow |

| Typical Hardness | Moderate (Shore D 70-85) | High (Shore D 85-95) |

| Viscosity | Low | Multiple options available |

| Pot Life | Long (30-60 mins) | Adjustable (2 mins - 4 hours) |

| Packaging | Small (100g – 5kg) | Bulk (5kg – 200kg drums) |

| Applications | DIY, Handicrafts, Art | Electronics, Electrical, Flooring, Adhesives |

5. How to Choose the Right Epoxy

When choosing epoxy, the purpose is everything.

If you are a crafter…

Choose:

If you are an industrial buyer…

Choose:

6. Processing Differences: Mixing, Curing, and Equipment

Understanding the practical handling differences is crucial for a successful outcome. The requirements for craft and industrial epoxies diverge significantly here.

6.1 Mixing & Pouring:

6.2 Curing Environment:

6.3 Safety & PPE:

7. Why Choosing the Wrong Type Can Be Costly

Using Craft Epoxy in an Industrial Setting: Leads to premature failure: softening under heat, cracking under stress, or rapid degradation when exposed to chemicals. This results in product recalls, downtime, and safety hazards.

Using Industrial Epoxy for Crafts: Often unnecessary, more expensive, and harder to work with (e.g., fast curing, difficult to mix, may require special equipment). It can ruin the aesthetic with its overly rigid or specialized properties.

8. Why Choose Us — We Formulate for Both Worlds

As a source factory manufacturer, we don't just sell epoxy; we provide tailored material solutions. We understand the nuanced requirements of both craft creators and industrial engineers.

For Craftsmen & Artists: We offer a range of high-clarity, bubble-free, and UV-resistant casting resins that are easy to use and deliver stunning results.

For Industrial Clients: Our OEM/ODM services allow us to engineer epoxies with specific properties: thermal conductivity, flame retardancy, flexibility, or custom curing profiles to fit your production line perfectly.

9. Conclusion: Partner with the Right Supplier

The choice between craft and industrial epoxy is a choice between aesthetic goals and technical specifications. By understanding your project's core requirements and partnering with a manufacturer that masters both domains, you ensure optimal performance, cost-effectiveness, and long-term success.

Ready to find the perfect epoxy for your project?

Explore Our Industrial Epoxy Solutions

Contact Our Technical Team for a Custom Quote

Hot News

Hot News2026-01-14

2026-01-06

2025-12-27

2025-12-26

2025-12-26

2025-12-25