1. Introduction

Whether you're encapsulating a delicate flower for a pendant, creating a glossy dome on a keychain, or potting a sensitive microchip for protection, you need a material that is brilliantly clear, reliable, and fast. UV resin is the modern solution that delivers on all fronts.

It's a single-component, modified acrylate liquid that remains workable until exposed to ultraviolet light (typically 365–405 nm), triggering an instant transformation into a hard, crystal-clear solid. This unique on-demand curing capability makes it the ideal choice for three core applications: vibrant DIY crafts, perfect surface doming, and precise electronic encapsulation.

2. What Is UV Resin & How Does It Work?

UV resin is a photopolymer based on modified acrylate. Unlike epoxy or PU resins, it does not require mixing, which eliminates measuring errors and drastically speeds up production.

Key Components & The Curing Mechanism

The magic lies in its chemistry. The resin contains photoinitiators—molecules that remain inactive until they absorb energy from specific UV wavelengths. Once energized, they trigger a rapid polymerization reaction, linking the other components into a solid, cross-linked network in seconds.

3. Key Technical Advantages: Engineered for Performance

Our UV resin is not just a material; it's a productivity solution. We've precisely engineered its properties to solve the core challenges in crafting, doming, and electronics assembly, delivering reliability and beauty in every drop.

3.1 Rapid Curing for Maximum Efficiency

Cures in 60-120 Seconds: Experience full hardening in just 1-2 minutes with a standard UV lamp, slashing waiting times from hours to moments.

Maximized Productivity: This rapid turnaround dramatically accelerates production cycles, reduces work-in-progress inventory, and is perfect for high-volume electronics potting or crafters who value efficiency.

3.2 Crystal Clarity, Guaranteed to Last

Water-Clear, Non-Yellowing Formulation: Cures to a brilliant, optically clear finish that showcases vibrant colors and fine details. Advanced UV stabilizers ensure long-term resistance to yellowing, preserving the aesthetic integrity of your products for years.

Ideal for Aesthetic-Critical Applications: From jewelry that demands lasting brilliance to electronic displays requiring unwavering clarity, our resin maintains its pristine appearance.

3.3 Precision-Engineered Viscosity

The Sweet Spot for Versatility: At 1100-1700 mPa·s, our resin boasts an ideal viscosity—thick enough to create perfectly rounded, non-runny domes on surfaces, yet fluid enough to easily penetrate and encapsulate delicate electronic components without air traps.

One Resin, Multiple Applications: This balance eliminates the need for multiple specialized products, simplifying your inventory and empowering both intricate crafts and technical tasks.

3.4 Industrial-Grade Strength

Rock-Solid Durability: With a Shore D hardness of 85±3, the cured resin provides a scratch-resistant, rigid shield that protects frequently handled items from wear and tear, and safeguards electronic assemblies from physical stress and environmental factors.

Reliable Protection: It's not just about looks; it's about creating durable goods and ensuring the long-term reliability of your electronic devices.

Want to verify performance with data? Download our detailed technical specifications sheet (PDF).

4. A Balanced View: Limitations & Smart Material Selection

UV resin is powerful, but it's not a one-size-fits-all solution. Understanding its boundaries ensures project success.

Key Limitations to Consider

UV Resin vs. Epoxy Resin: Your Selection Guide

| Feature | UV Resin | Epoxy Resin |

| Curing | UV light (instant) | Chemical reaction (hours) |

| Curing speed | 1-3 minutes | 12-72 hours |

| Transparency | High | High (but may yellow over time) |

| Operation | Simple (No Mixing) | Complex (Precise Mixing) |

| Thickness Restrictions | Recommended thickness per layer: <5mm | Can be poured in a single pour at greater thicknesses |

| Best for | Crafts, jewelry, quick repairs | Tables, floors, large molds |

5. Applications of UV Resin

UV resin is widely used in both crafts and industrial micro-applications:

5.1 DIY Crafts & Jewelry

5.2 Surface Doming

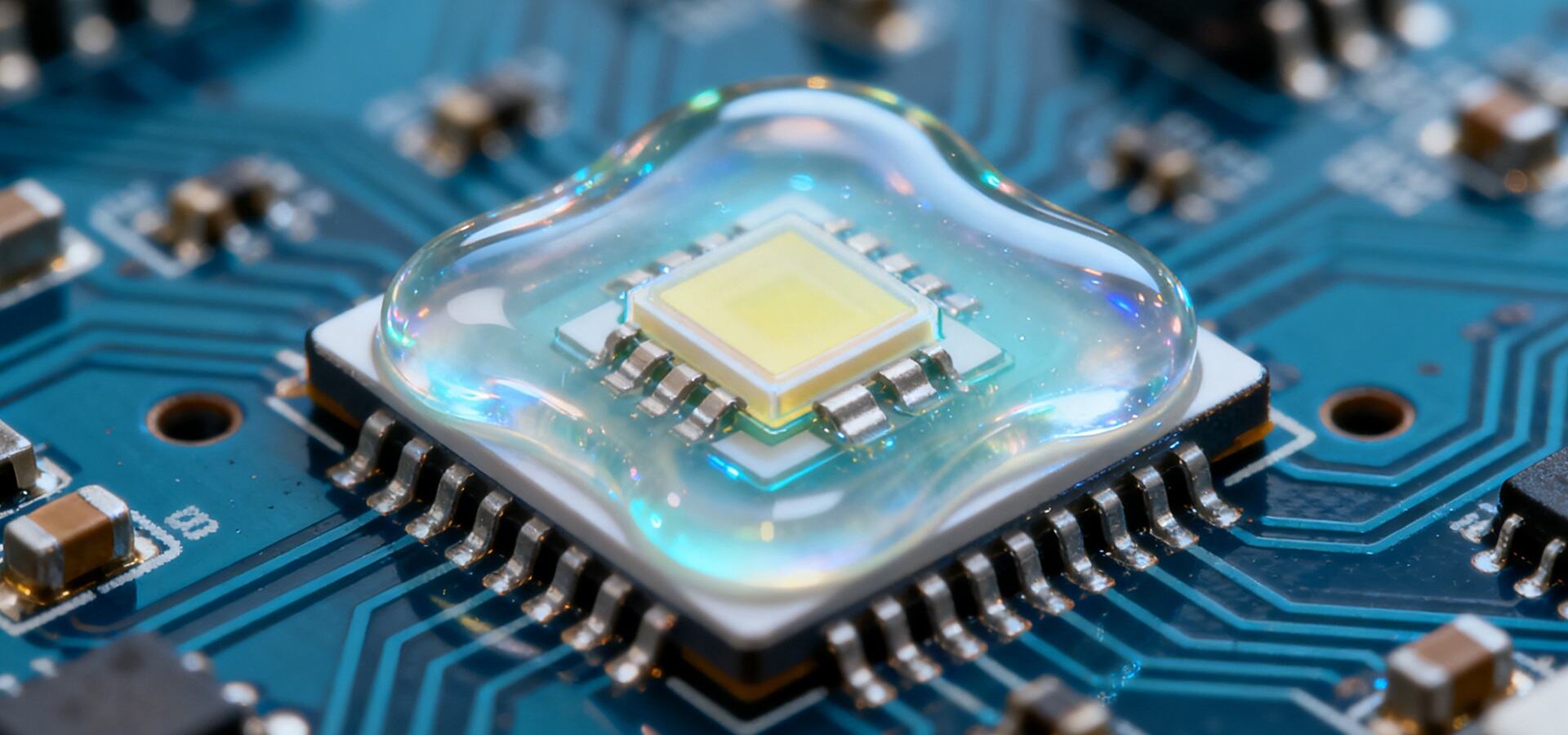

5.3 Electronic Potting & Sealing

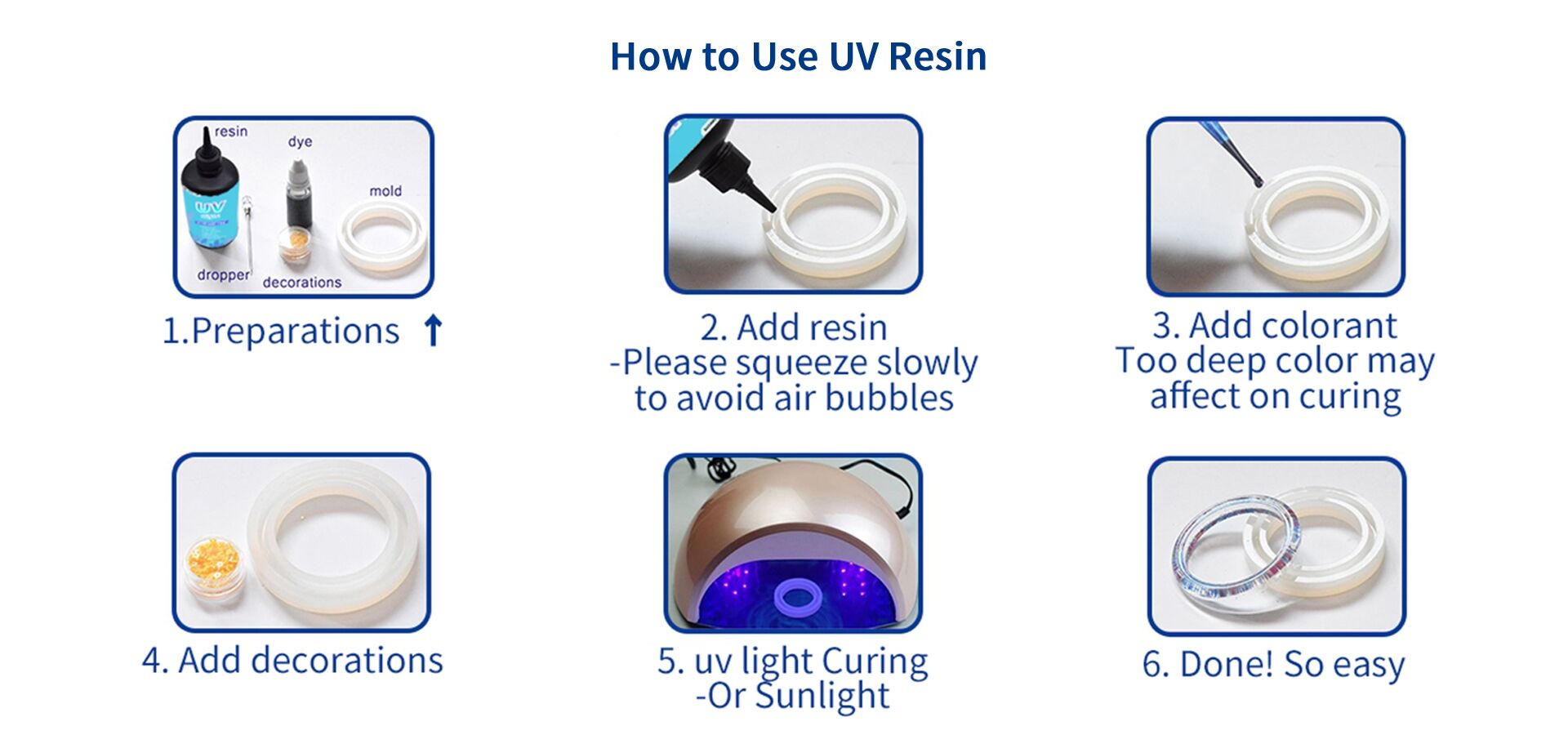

6. How to Use UV Resin (Step-by-Step)

6.1 Step-by-Step Instructions

6.2 Common Problems & Fixes

7. Selection Guide & OEM Customization: Your Path to the Perfect Resin

Start with Our Standard Grade

Our general-purpose UV resin is the perfect starting point for most applications in crafts, doming, and electronics.

Need Something Specific? We Create It.

Our true expertise lies in OEM/ODM customization. We engineer solutions from the molecule up to meet your exact needs:

Contact our OEM experts immediately to turn your requirements into a customized formulation.

8. Conclusion & Next Steps: Partner with Your Source Factory

UV resin bridges the gap between creative expression and technical precision. It empowers crafters to bring their visions to life with ease and provides engineers with a fast, reliable solution for modern miniaturized electronics.

As your source factory, we don't just supply a material; we provide tailored solutions and technical support across the UV, Epoxy, and PU spectrum to ensure your success, project after project.

Ready to Find Your Perfect UV Resin Match?

Shop Our Popular UV Resin for Crafts

Need a Custom Formula? Contact Our OEM Team

Hot News

Hot News2026-01-14

2026-01-06

2025-12-27

2025-12-26

2025-12-26

2025-12-25