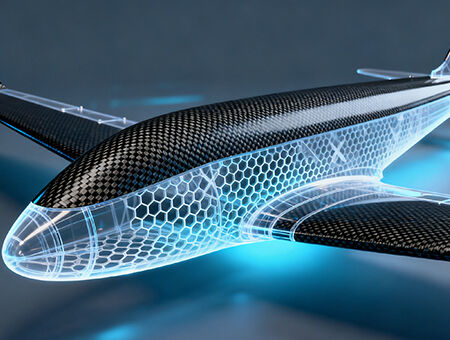

Why Our Resin Systems for Composites

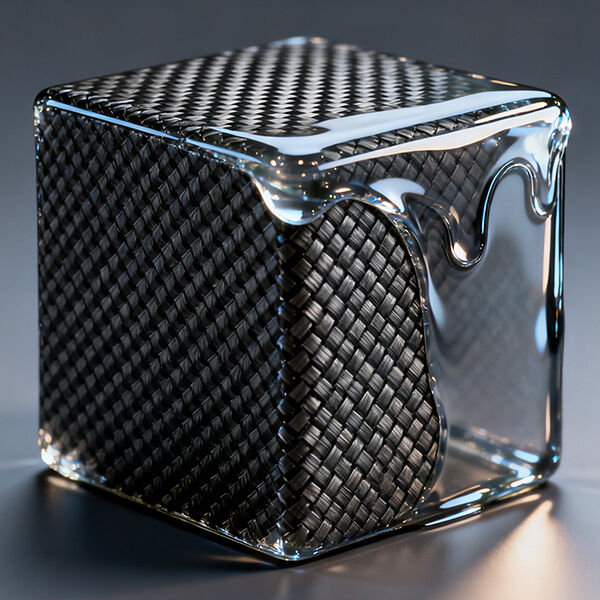

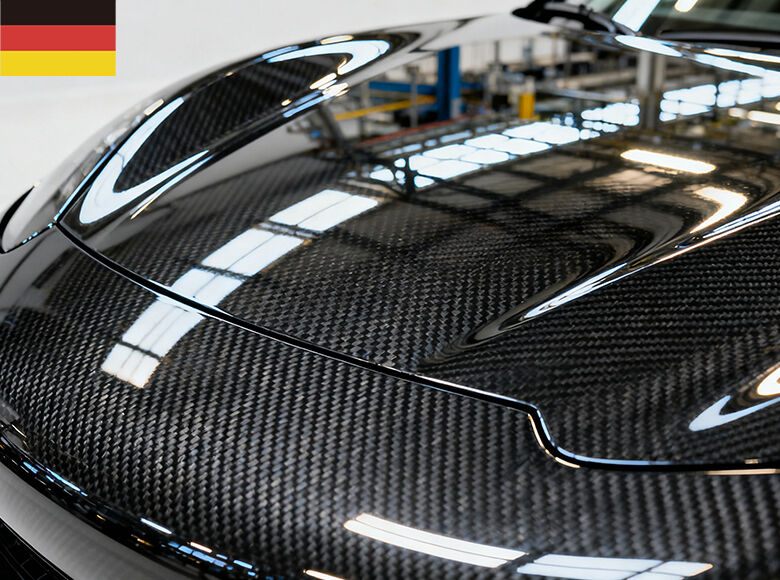

Engineered for Stronger, Lighter Composite Parts

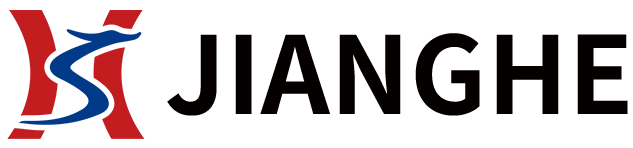

Advanced Wet-Out Technology

Ensures rapid and uniform fiber impregnation, minimizing dry spots, voids, and surface defects.

Aerospace-grade Strength

Delivers high tensile strength, interlayer bonding, and impact resistance for lightweight yet durable composite parts.

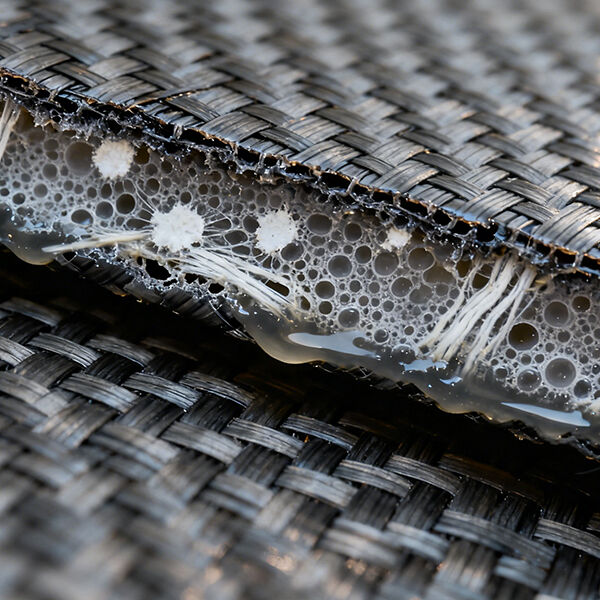

Precision Curing Control

Customizable pot life and curing speed for processes like vacuum infusion, hand layup, and automated lamination.