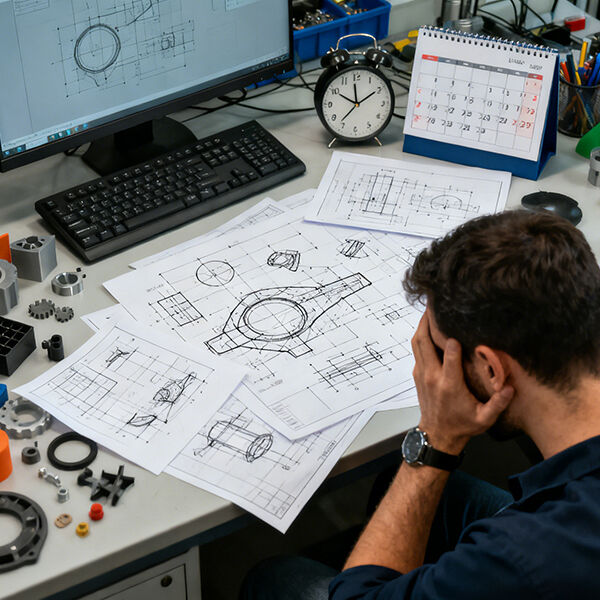

Why Our Solution Works

Engineered for speed, precision, and reliability.

High Precision & Stability

Material curing shrinkage is as low as <0.2%, making it suitable for validation of structural components, snap-fit positions, and assembly parts.

Multiple Mechanical Properties

Formulation adjustments can be made to regulate hardness, meeting diverse requirements for flexible components, rigid parts, and cushioning elements.

Professional Surface Finish

Supports grinding, polishing, spraying, metallic paint, and crystal coating treatments, suitable for both display and engineering applications. (Supports grinding, polishing, spraying, metallic paint, and crystal coating treatments, suitable for both display and engineering applications.)