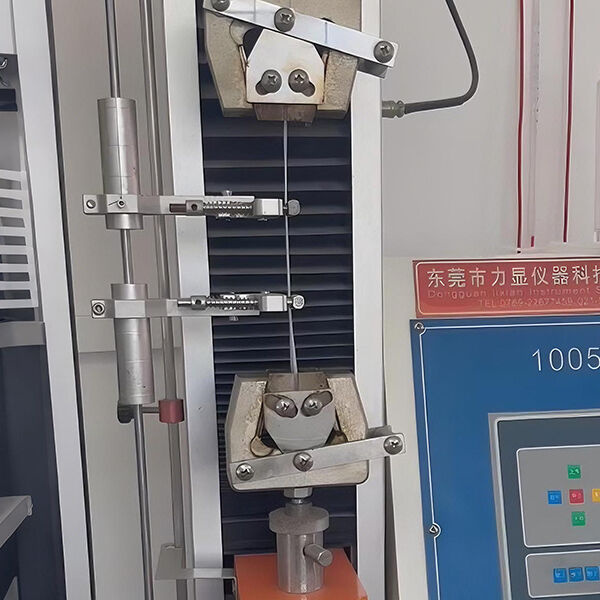

Why Our Mold Making Systems Are Trusted Worldwide

High Stability, High Detail, High Efficiency

Exceptional Detail Reproduction Capability

Breakthrough resolution perfectly replicates the finest textures and features.

Perfect Demolding Performance

Easy demolding without damage, ensuring perfect replication every time.

Extended Service Life

Durable formula significantly extends mold life, dramatically reducing per-piece costs.