3:1 Ultra Clear Self-Leveling Epoxy Resin for Countertop

Model: 318AB-9V-2 Mix Ratio: Weight Ratio 3:1

Key Features:

- 10cm Extreme Pour - Single pour up to 8-10cm thickness, industry-leading.

- Large Batch Mixing - One-time mixable capacity 10-15kg.

- Dual Ratio Flexibility - Offers both volume ratio 2:1 and weight ratio 3:1.

- Self-Degassing Mirror Finish - Advanced formula automatically eliminates bubbles for glass-smooth surfaces.

Technical Specifications:

| ☆ Pour Depth: Deep Pour Suitable | ☆ Pot Life: 6h |

| ☆ Hardness: Shore D 85 | ☆ Volume Ratio 2:1 |

Perfect For:

| ☆ Furniture & Large Surface Casting. | ☆ Commercial-Grade Custom Furniture. |

| ☆ Large Art Installations & Sculptures. | ☆ Industrial Molds & Component Manufacturing. |

| ☆ Scientific Research & Professional Display. | ☆ High-End Residential Customization. |

- Overview

- Recommended Products

-

Safety First: Operate in a well-ventilated area, away from ignition sources. Avoid skin and eye contact.

-

Mix as Needed: Estimate quantity based on the 40-minute pot life to avoid waste.

-

Adapt to Conditions: Preheat Component A if temperature <15°C; use heat-assisted curing if humidity >85% to prevent surface whitening.

- Safe Keeping: Keep out of reach of children.

-

Storage Conditions: Store in a cool, dry place below 25°C (77°F). Keep away from direct sunlight, heat sources, and humid environments.

- Packaging & Stability: The product has a shelf life of 6 months from the date of manufacture when stored unopened in its original container under recommended conditions. Once opened, reseal tightly and use as soon as possible. Do not leave exposed to air for extended periods.

-

Ultra-Thick River Tables: Custom 8-10cm thick tables for hotel lobbies, corporate headquarters, high-end restaurants.

-

Giant Bar & Countertops: Large integrated countertops for bars, clubs, exhibition halls.

- Commercial Display Cases: Ultra-thick glass-effect display platforms for museums, jewelry stores, luxury boutiques.

-

Large Resin Sculptures: 1-3m tall single-piece sculptures for art galleries and public spaces.

-

Geographical Art Installations: Ultra-thick geographical slice artworks with mountain, river, ocean themes.

- Modern Art Murals: Wall-embedded ultra-thick resin art murals.

-

Large Industrial Molds: Prototype molds for ship parts, automotive molds, large machinery components.

-

Architectural Decorative Elements: Ultra-thick decorative panels, column cladding for theaters, malls, hotels.

- Equipment Encapsulation: Waterproof and corrosion-resistant encapsulation for outdoor large equipment, communication base station.

-

Villa Stair Treads: Ultra-thick treads with embedded LED strips and decorations.

- Luxury Bathroom Vanities: Integrated oversized bathroom vanity countertops.

- Custom Art Flooring: Artistic resin inlays for floor areas.

Professional Epoxy Resin Manufacturing Experts

Shenzhen Jianghe New Materials Technology Co., Ltd. is a leading developer and manufacturer of high-performance polymer materials, including epoxy resin, PU resin, UV resin, and liquid silicone rubber. As an integrated source factory combining R&D, production, and sales, we operate a 20,000㎡ modern production base in Dongguan, certified with ISO9001 and other international standards. Supported by advanced equipment, a dedicated R&D team, and a strict QC system, we deliver over 25,000 tons of stable, high-quality, and cost-effective products annually to clients in over 100 countries. We specialize in customized formulations and OEM/ODM services, empowering industries from crafts and furniture to electronics and composites with reliable material solutions.

Key Advantages & Features

Highlight 1: Breakthrough Pour Thickness

Innovative low-exotherm curing system breaks traditional resin thickness limits, enabling single pours up to 8-10cm. This means no layering or waiting for ultra-deep river tables or large sculpture castings, truly one-time forming that dramatically shortens production cycles.

Highlight 2: Industrial-Scale Large Batch Production

Optimized for batch production and large projects, supports one-time mixing of 10-15kg. Combined with efficient stirring and pouring solutions, enables rapid completion of extra large tabletops or simultaneous production of multiple medium-sized projects, significantly boosting work efficiency.

Highlight 3: Flexible Dual-Ratio System

Innovative dual-ratio design offers both volume ratio 2:1 and weight ratio 3:1. The volume ratio facilitates quick estimation and operation, ideal for artistic creation; the weight ratio ensures higher mixing precision, meeting industrial-grade production requirements. Choose freely based on your project type.

Highlight 4: Self-Degassing Mirror Technology

Advanced self-degassing formula automatically guides bubbles to rise and escape during curing, eliminating need for complex vacuum equipment. Results in glass-smooth, ripple-free, dimple-free mirror surfaces, significantly reducing post-cure sanding and polishing.

Highlight 5: Durable & Easy Maintenance

Non-tacky cured surface naturally resists fingerprints and dust, requiring only simple wiping for daily care. Excellent heat and wear resistance ensures long-lasting beauty and functionality in high-use scenarios like tabletops and bar counters.

Detailed Technical Specifications

| Property | Part A | Part B |

| Color | Light blue, transparent | Light blue, transparent |

| Density (g/cm³) | 1.13±0.03 | 0.98±0.02 |

| Viscosity (mPa·s) | 1000±100 | 220±50 |

| Mix Ratio (By Weight) | A : B=3:1 (weight ratio), A : B=2:1 (by volume) | |

| Pot Life (100g, 25°C) | 6h | |

| Viscosity After Mixing | 500±50mPa.S | |

| Surface Dry | 50 hours | |

| Full Cure | 168 hours | |

| Hardness (Shore D) | 85 | |

| Water Absorption (%) | <0.1 | |

| Shelf Life | 6 months | 6 months |

Usage Guide & Steps

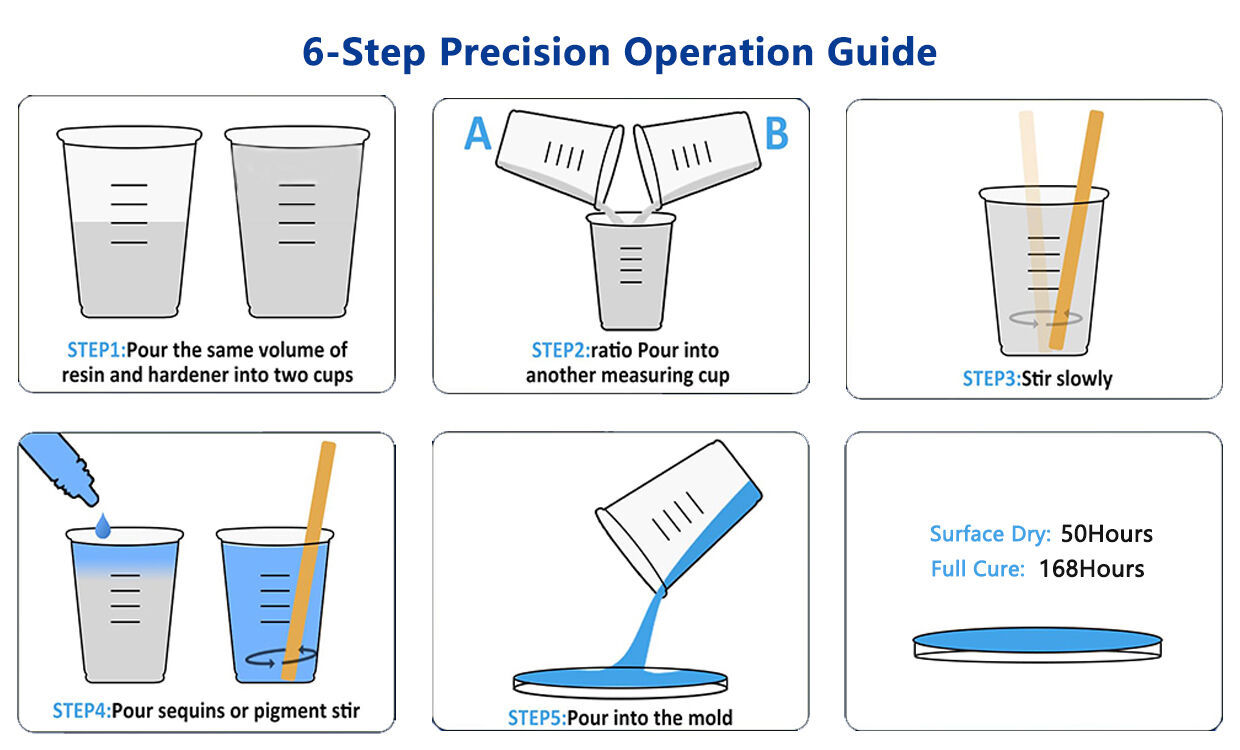

6-Step Precision Operation Guide

Step 1: Precise Measurement

Use a digital scale to accurately weigh at 3A : 1B ratio by weight.

Key Tip: Do not estimate by volume; weight ratio ensures proper curing.

Step 2: Intelligent Mixing

Stir slowly in one direction for 3-5 minutes.

Key Technique: Scrape container walls and bottom to eliminate unmixed spots.

Pro Tip: Slower stirring minimizes bubble formation.

Step 3: Rest & Debubble

Let stand for 3-5 minutes to utilize resin's self-debubbling properties.

Observation: Watch bubbles naturally rise and pop on surface.

Advanced Option: Use a heat gun to gently pass over surface for stubborn bubbles.

Step 4: Creative Coloring (Optional)

Add pigments, mica powder, glitter, etc.

Mixing Tip: Stir lightly to avoid reintroducing bubbles.

Test Advice: Test new pigments with small batches for compatibility.

Step 5: Elegant Pouring

Pour mixture slowly and steadily along mold edge.

Leverage Property: Resin's excellent self-leveling will spread naturally.

Avoid: Do not pour from height to prevent trapping air bubbles.

Step 6: Smart Curing

Room Temperature Cure: Surface dry in 50hrs @25°C, full cure in 168hrs.

Curing Care: Keep environment clean during curing to prevent dust contamination.

Safety, Handling & Storage Guidelines

1. For Safe Operation & Mixing

2.Storage And Shelf Life

Applications & Project Gallery

Commercial Furniture Manufacturing

Artistic Creation Field

Industrial Manufacturing Applications

High-End Residential Customization

OEM Customization Service

1.Customized formulation: Viscosity, flowability, curing time, hardness, transparency, color, and various functional additives (anti-yellowing, UV resistance, flexibility enhancement, flame retardancy, etc.) can be adjusted according to needs to meet different industry application scenarios.

2.Packaging Customization: Multiple packaging sizes are available to suit your production scale, including 1kg, 5kg, 20kg, 25kg, and 200kg drums. All packaging follows international shipping standards to ensure safety and durability.

3.Private Label: Supports brand customization, including bottle label design, outer packaging printing, and logo labeling, helping brand owners and wholesalers quickly build their own brands and enter the market.

4.Supplies and Kits: Pre-mixed kits (such as resin + resin pigment + mold + tools, etc.) are provided according to your end product.

5.Color matching and functional additives: Color matching services are supported, and special effects such as metallic, transparent, and pearlescent colors can be added, as well as various functional additives such as UV stabilizers, defoamers, scratch and abrasion resistant agents, and flame retardants.

6.Sample support: We support sample orders for performance testing before mass production. This ensures compatibility with your process, equipment, and application requirements.

7.Technical consultation and process guidance: Engineers provide one-on-one technical guidance on construction suggestions, curing conditions, mixing ratios, application processes, etc., to help you solve practical problems.

Why Choose Our Customization Services?

1. Fast Response — Initial Technical Proposal Within 72 Hours

Once we receive your requirements, our engineering team will provide an initial formulation direction or technical recommendation within 72 hours. This significantly shortens your R&D cycle and speeds up time-to-market.

2. Cost Advantage — 15–30% Lower Than Trading Companies

As a factory with no middlemen, we offer highly competitive OEM pricing while maintaining strict quality standards. Ideal for distributors, factories, and brand owners seeking stable and scalable supply.

3. Confidentiality Guaranteed — 100% NDA Support, Formulations Never Disclosed

Every custom project can be secured with an NDA. We protect your formulations, data, and intellectual property with strict confidentiality standards and never share them with third parties.

4. End-to-End Control: One-Stop Service from Raw Materials to Delivery

Full in-house control over formulation, production, filling, private labeling, packaging, and logistics ensures consistent quality and stable supply.

5. 17+ Years of Material Manufacturing Expertise

With deep expertise in epoxy resin, PU resin, UV resin, liquid silicone rubber, and gypsum powder, we understand the performance needs of various industries including electronics, crafts, automotive, LED, molds, and flooring.

6.Technical Core: In-House R&D Center and Engineering Team

Experienced application engineers provide one-on-one support in formulation tuning, process optimization, and troubleshooting to ensure optimal performance.

7. Stable Quality — ISO9001 Certified Production

We follow strict quality control standards under ISO9001:2015. Every batch is traceable, stable, and tested to meet your specifications.

8. Fast Sampling & Flexible MOQ

We support rapid sample production and low-MOQ orders, reducing risks for new product launches, distributors, and factory procurement.

9. Brand Empowerment: Complete Private Label and Packaging Customization

Full white-label services including label design, multi-size packaging, and brand logo printing to help you build a professional brand image with ease.

10.Global Delivery: Scalable Production and International Logistics Network

Own large-scale production facilities paired with a mature global logistics network ensure stable output and on-time delivery worldwide.

If You Need Customized Packaging Or Other Specifications, Please Contact Us.

FAQ:

1.Q: Volume ratio 2:1 or Weight ratio 3:1 – which should I use?

A: For ultra-thick pours (5cm) and large batches (10kg), we strongly recommend the Weight Ratio 3:1. It offers higher precision, ensuring uniform curing reaction throughout the large volume and minimizing core defects from ratio errors. The volume ratio is suitable for smaller batches or artistic projects where extreme precision is less critical.

2.Q: How to ensure thorough mixing for a single 15kg batch?

A: We recommend the "Three-Stage Mixing Method": 1) Initial mixing with a large paddle mixer; 2) Transfer to a larger container for secondary folding/stirring; 3) Final light stirring before pouring. Using industrial mixing paddles with edge scrapers yields the best results.

3.Q: Will the center overheat when pouring 10cm thick?

A: No, it will not. This is a core technological advantage of this product. Its specially formulated low-exotherm system is optimized so that even under extreme conditions (10cm thickness, 15kg batch), the peak center temperature remains within a safe range (typically <55°C), well below the threshold for yellowing or cracking.

4.Q: How is surface flatness guaranteed in such thick pours?

A: It relies on two key properties: Exceptional Self-Leveling and Precise Viscosity Control. The resin naturally levels over very large surface areas while maintaining good edge definition without excessive sagging. Minor leveling adjustments can be made within the first 24 hours after pouring.